Zhangqiu mingyuan machinery co.,LTD Manufacturer

Company Introduction

Zhangqiu Ming Yuan Machinery Co., Ltd. is located in Zhangqiu, Lantau Peak, Zhangqiu Economic Development Zone, the transportation facilities and beautiful environment. Company was founded in 1995, the company covers an area of 25000 square meters, is the production of forging flange professional company, the existing fixed assets of 60 million, annual output of more than 10000 tons. The main products are: Japanese standard, German standard, American Standard, Russia standard can also provide drawings or sample production and processing according to customer. Products are exported to Japan, the United States, Germany, South Korea, Russia, Brazil, South Africa, more than 20 countries, and regions, product quality by the majority of customers praise and trust.

The company professional strong technical strength, rich experience and professional equipment, with high-quality international most advanced forging machinery processing, assembly, testing and packaging production lines, product quality in line with national and international standards, and has obtained ISO9001-2000 quality management system certification, with the German PED certificate, the license of special equipment production Chinese, pressure vessel production license card。

Companies to survive by quality, rely on the credibility of development. Will continue to introduce advanced technology and development of new products, to provide customers with high quality and high precision quality products. The company is willing to work with you to create brilliant.

Main production equipment:

The material mechanical performance testing equipment: Germany imported portable spectrum direct reading instrument, carbon sulfur analyzer, electro-hydraulic universal testing machine, hardness tester, ultrasonic testing, magnetic particle testing, impact testing, water depth monitoring, roughness instrument.

Cutting workshop: have 7 CNC sawing machine、Equipped with 10 tons of traffic car one 、3 tons of traffic one 。

Forging equipment:3 tons of plywood with 1T mechanical hand hammer、2000mm ring rolling machine,2 tons of plywood hammer with 1000mm grinding ring machine,560kg air hammer with 600mm grinding ring machine,150kg air hammer with 300mm grinding ring machine,forklift truck 2 Natural gas environmental protection furnace 3 ,Do heat treatment.

Machine shop:21 sets of CNC lathe Plain lathe 5,General numerical control drilling machine 13 sets、High speed U drill 2 sets

QC packing workshop::Typewriter 3、2 sets of packing machine、1000mm flange cleaning machine 1 sets、Paint oven 1。

Company staff:Production technical personnel 16 people、Production line workers 162 people Management personnel 11 people,Packaging quality inspection staff of more than 20 people。

The company covers an area of 25000 square meters。

Production range: PL flat flange 15-2000

SO slip-on flange15-2000

WN welding-neck flange15-2000

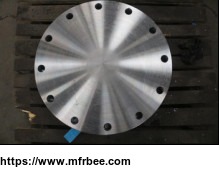

BL blind flange15-2000

Advantages: Germany imported portable spectrum direct reading instrument test material

Forging ring mill to reduce the cost of material ratio control

CNC production of the company wide precision machining, strict product quality.

Drilling using high speed U drilling precision machining to ensure the quality of drilling, with the international practice.

The company set up the Department of foreign trade, is responsible for professional sales and after-sales service to customers

Company specializing in the production of high precision flange, do the same industry, the highest quality and best quality products