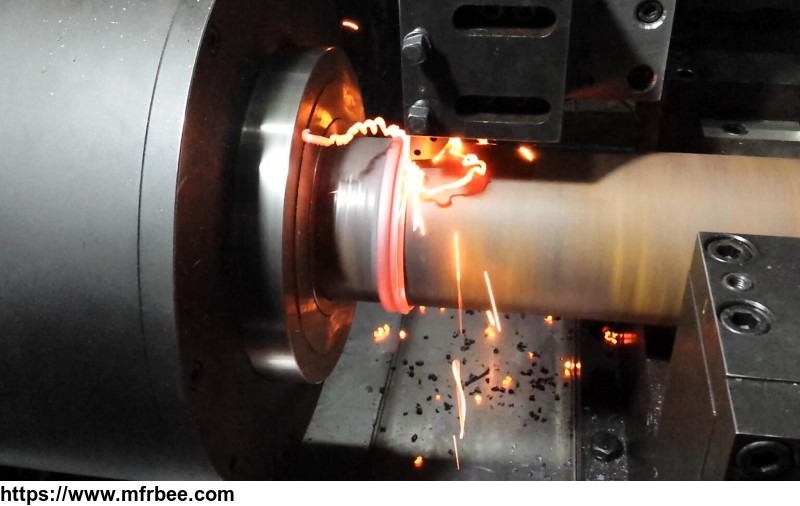

Friction welding machine

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

- FOB Price

- USD $20,000.00 / Piece

- Packaging

- wooden case

- Delivery

- 30 Days

Specifications

Friction Welding Machines use for welding the:

power transition joints / bimetallic bearing /

ball pin, ball stub / cardan joint / CV joint / Cu-Al Cable lug

steering track rod / steering linkages / auto semi-axle /

dashpot / sunbber / supercharger of turbine shaft / S shape cam shaft /

multigang gear shaft / cutter blank, workblank, other blanks /

box spanner, carriage wrench, socket spanner / deformed steel bar /

jackrod, drill pipe, drill stem / sucker rod / valve body / motor shaft /

fuel injection tubing connection / dumbbell..........And more other welding parts.

Friction Welding Performance Presentation

Economical Type:

MCH-A series of economical type friction welding machine is the independent

research and development models in 1998, the model is mainly used for a variety of shaft,

pipe-type parts welding. It can weld a wide range of metals, especially suitable for welding dissimilar metals,

usually easier to achieve with the same base material strength of welded joints.

Precision Type:

MCH-SJ series precision friction welding machine is our independent development of new products in 2012.

The product uses electro-proportional servo spindle drive system and hydraulic control system. By servo spindle drive system,

the spindle speed is increased by more than 40%. Closed-loop control of each cylinder can work through electro-proportional

hydraulic control system to ensure stable and reliable welding parameters.

FUNCTION:welding phase angle control / Double sides welded simultaneously function / automatic loading and unloading / automatic removal of welding flash.

- Country: China (Mainland)

- Business Type: Manufacturer for Friction Welding Machine

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year: 2002

- Address: No.500 Xingfang Rd,Xingta Industrial park,Jinshan District,Shanghai,CHina

- Contact: Frank Xie