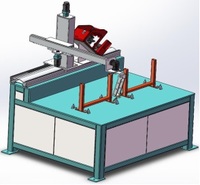

4 axis Automatic Welding Machine for Tipper Trailer

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

1. 4axis structure, and welding torch is installed in 4axis structure.

Workpiece is fixed in the mould, welding torch will rotate. Welding torch will be adjusted up and down, forward and backward, left and right

and angled movement.

2. The project is run by numerical control system. Welding type, specification and other parameters can be setup in one integrated control panel. There will be fault alarm and indication during

welding process, such as stuck wire, blocked wire, etc.

3. Push-type wire feeder works stably. Machine is with high welding voltage and slow wire feeding performance, which guarantees reliable arc igniting. Machine is also with low welding voltage and

low welding current for filling crater.

4. Machine is driven by AC servo motor. Servo motor reducer will guarantee smooth running during process of welding.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:European Union

- Founded Year:2011

- Address:Middle Mingjia Road, Qihe Economy Development Zone, Shandong, China

- Contact:Peter zhu

Other products from QIHE GAOXIN HAOYU CNC MACHINERY CO., LTD

Relate products of 4 axis Automatic Welding Machine for Tipper Trailer

4 axis welding machine

4 axes robot Application Welding workpiece: Component name: Wheeler swing arm Product size: min 100mm -max 600mm MIG welding Machine can work continuously for 24-hour. Welding Requirement Welding seam will be flat welding or fillet welding. Welding process does not allow the ...