Knitted Wire Mesh

Specifications

Knitted wire mesh fabric is normally knitted form round or flat wires ranging in various diameter. It is used in cleaning and air-filtration applications where large surface areas of wire

fabrics are needed. The wire diameter of knitted wire fabric affects flow, dirt holding capacity and pressure drop. In general, knitted mesh with larger wire diameter allows for higher flow but

provides lower dirt holding capacity, also larger diameter wire is less expensive. Therefore, a balance must be struck between using a higher density filter for higher cost fine wire or lesser

density filter using lower cost heavy wire.

Benefits: Knitted wire mesh filters offer low resistance and maximum efficiency up to 98%. Knitted wire demister pads can be designed with specific density and materials to optimize flow capacity

and provide efficient filtration.

Materials Applied: Stainless steel, monel, brass, aluminum and tin or copper coated steel.

Forms of Supplies:

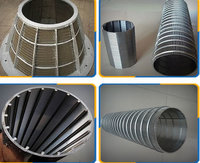

Knitted wire mesh can be deformed into demister pads, or rolled into various shapes and grades for industrial filtration, mist eliminators, breathers and mufflers.

Our knitted wire mesh is made from all material available in wire shapes for processing of the following parts:

Filters Oil and Air Breather Elements,Catalytic Converter Mesh Insulator Blanket Mesh,Mufflers and Silencers,Copper Mesh Oil-Bath Separators,Mist Elimination Pads Ground Wire Mesh.

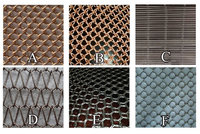

Main Materials Applied for Knitted Mesh:

Monel knitted wire mesh has good corrosion resistance in all extreme environments and it is reasonably conductive and is tough with high tensile strength, giving good wear characteristics.

Knitted wire mesh made of tinned copper clad steel has the best shielding performance of all wires used in knitted meshes, combining low contact resistance with a small degree of permeability. It

is not suitable for highly abrasive applications where the TIN plating may wear away to expose the copper. The corrosion resistance of tinned copper clad steel knitted wire mesh is suitable for

most applications.

Aluminum knitted wire mesh is mechanically weak and will readily take a compression set and this combined with its readiness to form a non-conducting oxide.

Stainless steel knitted mesh is often used as a protective final layer over the other knitted mesh gasket, materials on order to provide a wear-resistant contact surface.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Asia

- Founded Year: 1998

- Address: 16 Shunhe West Road, Dezhou, Shandong, China

- Contact: Arthur Abraham