Wedge Wire Screen

Specifications

Wedge wire, or slotted profile wire, is the most durable mining screen media with precise retention ratings. Wedge wire elements are particularly suited for critical low maintenance

applications. As a result of their V construction, they are used in many instances where manual cleaning is necessary but might damage other types of media.

As welded wedge wire is the most popular mining screen due to it strength, welding is performed from overhead gantries using automatic wire feeding welding machines. Welding quality and accurately

fitted connections reflect the care and skill exercised by our employees.

Woven wedge wire screens supplied by Atlas feature precise profile shapes and slot spacing which mean greater open area and reliable slot openings.The screens are also non-plugging, self-cleaning

and abrasion-resistant.Woven wedge wire screens are manufactured in AISI 304 and AISI 316L stainless steel, as well as other metal materials.

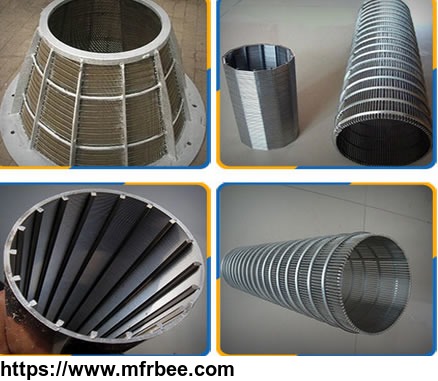

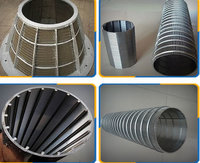

Wedge wire screen with V profile is engineered in various forms of filtering elements or cartridges in flow control. The mostly found shapes in uses are stainless steel wedge wire panels,

cylinders, baskets, tubes and curved sieve bend in arc forms. Mainly serve mine, coal development, water treatment and well screening industries.

wedge wire filter strainer baskets are commonly used in existing strainer or filter cartridges for various flow control.

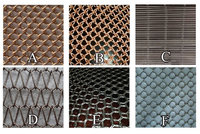

Features and Benefits of V Profile Wedge Wire Compared with Perforated Filter Basket and Woven Mesh Baskets Elements:

The welded wedge wire screen baskets provide more sufficient opening than the perforated metal baskets. It is stronger and can bear heavy loading pressure than the woven mesh filter baskets. The

wedge wire basket can work with both benefits of the perforated and woven mesh filter elements and avoid the shortcomings. It is stronger, has more aperture and pressure differential levels can be

achieved by variety of the slotting. Also it is economic.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Asia

- Founded Year: 1998

- Address: 16 Shunhe West Road, Dezhou, Shandong, China

- Contact: Arthur Abraham