Welded Wire Lath

Product Quick Detail

- FOB Price

- USD $500.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

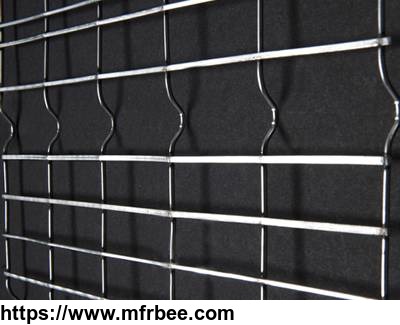

Welded wire lath, together with its accessories, is used behind stone, traditional stucco or tile installations. The metal lath is to enhance the reinforcement of plaster and exterior stucco

cladding, and reduce cracking during and after the construction.

Generally, the welded wire lath could be flat and self-furring, with or without backing, reinforced or not reinforced are all supplied. The backing is either absorptive or water resistant. Water

resistant backing provides protection against wetness during stucco curing. The welded wire lath backing paper must has a bursting strength which is no less than the strength to move under normal

hand or machine pressures.

A worker with gloves is extending stucco over our self-furring welded wire lath.

WWL-01: With the help of welded wire fence, stucco and plaster could be fixed on more steady.A part map of welded wire lath used on wall, with black water resistant paper behind the lath.

WWL-02: Backing paper used behind the welded wire lath for a water resistant or absorptive effect.

Types of Welded Wire Lath: flat welded wire lath and self-furring welded wire lath.

A flat welded wire lath is used on the surface of wall with stucco covered it.

WWL-03: Flat welded wire lath used on the surface of wall made from grass and soil.A part map of self-furring welded wire lath with black backing on the bottom.

WWL-04: Self-furring welded wire lath with backing

Welded Wire Lath Specification:

Materials: cold-drawn steel wire.

Surface finish: zinc coating conforming to specification ASTM A641/A641M.

Welded wire diameter: 0.0625 in. (1.588 mm).

Table 1 – Welded wire lath with square mesh opening

Mesh opening size Thickness Width Width variation Length Length variation Weight

Sheets Rolls

not more than 2 in. (51 mm) by 2 in. (51 mm) 1?8 in. (3.2 mm) ± (0.8 mm) 28 in. (700 mm) to 54 in. (1370 mm) 0.748 in. (19 mm) No less than 48 in. (1200 mm) No more than 150 ft (45.720 m) 0.748 in.

(19 mm) 1.14 lb/yd2 (0.618 kg/m2)

Welded wire lath installation method (per ASTM C993 and ASTM C1063):

The transverse wire of the upper lath should be aligned 1/8'' to 3/16'' below the transverse wire of the lower lath. The overall thickness of lath remains within 1/4'' furring plane (three 38

3/8'' lath widths span 115 1/2'' cover a 9' 3'' wall height, including overlaps).

Attachment of the backing and welded wire lath shall permit full embedment, in not less than 1?4 in. (6 mm) of plaster, of not less than one-half of the total length and width of the wire.

Note: The thickness of the embedment of the lath and plaster shall be measured from the back plane of the back wire, exclusive of furring, to the backing or surface of the substrate.

Three pictures of installation are included, which illustrate proper position of overlap as stated above.

WWL-05: The proper thickness, width, length of the overlap of upper and below lathes should be paid more attention in the process of installation.

Features:

Increase stucco and plaster embedment.

Reduce stucco and plaster cracking by transferring pressure.

Fur depth of 1/4" provides for ideal stucco embedment.

Efficient working, easily cuts with scissors or a knife.

The easy-to-handle character enhances workers' safety, satisfaction and productivity.

Easy to installation for common residential construction (9 feet 3 inches wall height).

Fire resistant.

Cold-drawn steel wire being greater strength.

Welded technique helps all wires to provide a reinforcing truss.

Welded joints of accessories provide structural integrity and superior stiffness.

Flat-furring design ensures there will be no damage to the vapour barrier.

Packaging and marking (per ASTM C993):

The backing shall be attached to the lath to prevent accidental removal during shipping, handling or installation.

Welded wire lath would be packaged in bundles, rolls, or pallets.

Bundles, rolls, or pallets all marked with metal tags or paper tags.

Plastic or metal banding, or paper wrapping on rolls.

2 in × 2 in welded wire lath panels are packed in pallets, with plastic film and fastener wrapped.

WWL-06: Welded wire lath packaged in pallets.Welded wire lath panels packed in rolls, being put on wooden pallets, and stored in warehouse.

WWL-07: Welded wire lath packaged in rolls.

- Country: China (Mainland)

- Business Type: Trading Company

- Market: Americas

- Founded Year: 1987

- Address: East industrial Zone, Anping, Hebei, China.

- Contact: yan dong