Close Mesh Steel Grating for Wheeled Equipment Access

Product Quick Detail

- Place Of Origin

- china

- FOB Price

- USD $500.00 / Piece

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

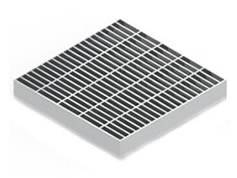

Standard steel bar grating has the 1-3/16\" and 15/16\" bearing bar spacing. There is a type of steel bar grating, which has closer bearing bar spacing for heavy duty and special requirements applications, that is close mesh steel grating.

Compared with standard steel bar grating, close mesh steel bar grating has higher load capacity and can be used in more applications. The closer spacing can permit the wheeled equipment passing, including the baby carriage, roller skates. Additional, the close mesh steel grating is suitable for the ADA (American Disability Act) standard. It can allow the wheel chairs get through fluently.

Material of close mesh grating

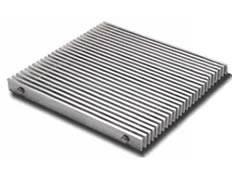

The materials of close mesh steel grating can be carbon steel, aluminum steel and stainless steel which can be used in different applications. The carbon steel is the most economical type among the three types and it can be galvanized or painted to increase the corrosion resistance. Aluminum close mesh grating features lightweight and corrosion resistance. Stainless steel close mesh grating is relatively more expensive than the other types, but its alkali and acid resistance performance allows it can be used in the harshest environments.

Type of close mesh grating

According to the different fabrications, the close mesh steel bar grating can be divided into welded close mesh grating, swage-locked close mesh grating and press-locked close mesh grating. Welded close mesh steel grating and press-locked close mesh grating has same bar size and bearing bar spacing. The swage-locked close mesh grating has its own bar size and bearing bar spacing.

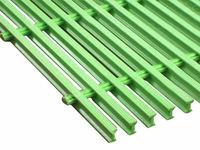

Welded close mesh grating.

Pressed locked close mesh grating.

Swage-locked close mesh grating.

Specifications

- Material: carbon steel, aluminum steel and stainless steel.

- Surface treatment: galvanized, painted, mill finished and other treatment.

- Type: welded close mesh grating, swage-locked grating and press-locked grating.

- Surface type: plain type and serrated type.

- Bearing bar spacing: 13/16\", 11/16\", 5/8\", 1/2\" and 7/16\".Features

- Closer spacing for convenient access of all shoes type, especially the high heel shoes.

- High load carrying capacity.

- Aluminum close mesh grating for lightweight and corrosion resistance.

- Stainless steel close mesh grating for acid and alkali resistance.

- Serrated surface for slip resistance.

Applications

- Close mesh steel grating is widely used as walkways, platforms, which are convenient for wheeled equipment pass, such as bicycles, wheel chairs, baby carriage and so on.

- Close mesh steel grating is widely used as trench covers, drainage covers, which can block large wastes from entering the trench and affect the normal drainage system.

- Close mesh steel grating is widely used as stair treads in the industrial and commercial applications.

- Close mesh steel grating is suitable for ADA (American Disability Act) standards.

Close mesh grating can block large wastes entering the trench.

Close mesh grating is widely used as stair treads in factories.

Close mesh grating is available for wheel equipment easy passing.

Close mesh with high load carrying capacity is widely used as platform.

- Country: China (Mainland)

- Business Type: Trading Company

- Market:Asia

- Founded Year:1992

- Address:East industrial Zone, Anping, Hebei, China.

- Contact:zhang yu