CNC Milling Cutter Solid Carbide End Mill Cutting Tools

Product Quick Detail

- Place Of Origin

- China (Mainland)

- FOB Price

- USD $3.00 / Piece

- Minimum Order

- 10

- Packaging

- 1pcs each PVC box

- Delivery

- 15 Days

Specifications

Product Description

High Performance CNC Solid Carbide Cutting Tools

1. Carbide square end mill, ball end mill, aluminium end mill

Rough end mill, special tools

2 TIAIN Coating, Tin coating and Diamond coating with high quality

3. Micro Grain for HRC45-HRC65

4- Fast Delivery and good price

Speciafications

Chemical Composition: 8%-10%Co-WC

Physical and Machinal properties: Density: 14.40-14.65g/cm3 Hardness: 91-93 HRA Flexural Strength: 3200-4000N/mm2

Organizational Structure: WC mean grain size: 0.5-0.6um

Corresponds to International Standards: K20-K30, K20-K40

Suitable for: Machining of cast iron, nonferrous alloy, nonferrous metals, fireproof alloy, Titanium alloy, alloy steel, carbon steel and other non-metallic. It has suitable for finishing processing the grooves and side. Meanwhile, it can be processing in high speed and high efficiency which the material HRC>60

The helix angle of the aluminum endmill is divided into a 45 degree helix angle and a 55 degree helix angle. The 45 degree helix angle is usually called a double ligament. The 55 degree helix angle is usually called a ligament. Double ligament aluminum end mill more commonly used, more rigid, single ligament aluminum end mill is more sharp, less rigid and double-edged with aluminum end mill nose end mill with R0.5 and R1, generally no special indication on the default is R0.5, R0.5 round nose mill is also more commonly used flat end mill has two edges and four blades, four blade more commonly used, generally no special instructions, the default for the four blade flat end mill aluminum end mill is also divided into three blades and two Blade, no special instructions, but also the default is the three-edged. Two-edged aluminum blade is smoother

High Performance CNC Solid Carbide Cutting Tools

1. Carbide square end mill, ball end mill, aluminium end mill

Rough end mill, special tools

2 TIAIN Coating, Tin coating and Diamond coating with high quality

3. Micro Grain for HRC45-HRC65

4- Fast Delivery and good price

Speciafications

Chemical Composition: 8%-10%Co-WC

Physical and Machinal properties: Density: 14.40-14.65g/cm3 Hardness: 91-93 HRA Flexural Strength: 3200-4000N/mm2

Organizational Structure: WC mean grain size: 0.5-0.6um

Corresponds to International Standards: K20-K30, K20-K40

Suitable for: Machining of cast iron, nonferrous alloy, nonferrous metals, fireproof alloy, Titanium alloy, alloy steel, carbon steel and other non-metallic. It has suitable for finishing processing the grooves and side. Meanwhile, it can be processing in high speed and high efficiency which the material HRC>60

The helix angle of the aluminum endmill is divided into a 45 degree helix angle and a 55 degree helix angle. The 45 degree helix angle is usually called a double ligament. The 55 degree helix angle is usually called a ligament. Double ligament aluminum end mill more commonly used, more rigid, single ligament aluminum end mill is more sharp, less rigid and double-edged with aluminum end mill nose end mill with R0.5 and R1, generally no special indication on the default is R0.5, R0.5 round nose mill is also more commonly used flat end mill has two edges and four blades, four blade more commonly used, generally no special instructions, the default for the four blade flat end mill aluminum end mill is also divided into three blades and two Blade, no special instructions, but also the default is the three-edged. Two-edged aluminum blade is smoother

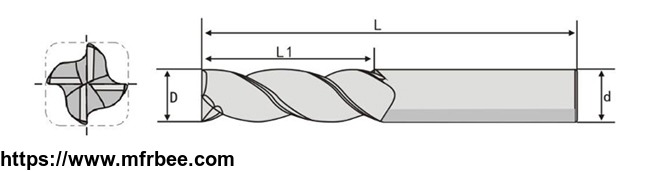

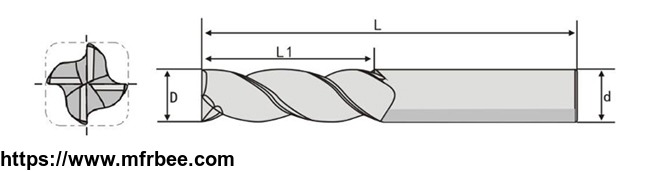

Tungsten steel coating 4 Flute ball nose mill(Standard length type,Extended Type)

| D | D | L1 | L |

| 4 R0.5/R1 | 4 | 10 | 50 |

| 4 R0.5/R1 | 4 | 12 | 75 Extended type |

| 4 R0.5/R1 | 4 | 16 | 100 Extended type |

| 5 R0.5/R1 | 6 | 13 | 50 |

| 6 R0.5/R1 | 6 | 15 | 50 |

| 6 R0.5/R1 | 6 | 18 | 75 Extended type |

| 6 R0.5/R1 | 6 | 20 | 100 Extended type |

| 8 R0.5/R1 | 8 | 20 | 60 |

| 8 R0.5/R1 | 8 | 24 | 75 Extended type |

| 8 R0.5/R1 | 8 | 25 | 100 Extended type |

| 10 R0.5/R1 | 10 | 25 | 75 |

| 10 R0.5/R1 | 10 | 30 | 100Extended type |

| 12 R0.5/R1 | 12 | 30 | 75 |

| 12 R0.5/R1 | 12 | 35 | 100Extended type |

| 14 R0.5/R1 | 14 | 35 | 80 |

| 14 R0.5/R1 | 14 | 40 | 100Extended type |

| 16 R0.5/R1 | 16 | 40 | 100 |

| 18 R0.5/R1 | 18 | 40 | 100 |

| 20 R0.5/R1 | 20 | 45 | 100 |

Product detail display:

Characteristic:

*Using high quality new edge, smooth surface, the edge of the special fine grinding wheel grinding, 200 times larger than the lack of micro, the coating has better corrosion resistance!

*Ultrafine tungsten steel base material with high strength and abrasion resistance, can be of 50 HRC below the material heat treatment direct rough processing and fine processing. We can supply HRC50 / HRC55/HRC58/HRC60 and HRC62 end mlling.

*4 blade corner radius End Mill is mainly based on the side pin.

*Tolerance in 0-0.02 negative rake angle design, taking into account the edge strength and sharpness, with large core design, enhanced tool steel, cut the pin and the pin is more stable, reduce the tool change times, improve the machine moving rate, save the production process.

*Cutting edge angle to take the latest technology, strict scientific groove design, making the tool wear resistance and cutting strength to get a perfect combination.

*Using high quality new edge, smooth surface, the edge of the special fine grinding wheel grinding, 200 times larger than the lack of micro, the coating has better corrosion resistance!

*Ultrafine tungsten steel base material with high strength and abrasion resistance, can be of 50 HRC below the material heat treatment direct rough processing and fine processing. We can supply HRC50 / HRC55/HRC58/HRC60 and HRC62 end mlling.

*4 blade corner radius End Mill is mainly based on the side pin.

*Tolerance in 0-0.02 negative rake angle design, taking into account the edge strength and sharpness, with large core design, enhanced tool steel, cut the pin and the pin is more stable, reduce the tool change times, improve the machine moving rate, save the production process.

*Cutting edge angle to take the latest technology, strict scientific groove design, making the tool wear resistance and cutting strength to get a perfect combination.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas,Asia,Europe

- Founded Year: 2004

- Address: 1314-13F Liye.rd Songgang,Baoan,Shenzhen,Guangdong,China

- Contact: CHEN CHANGHAI