Superhydrophilic and Superoleophobic Separation Membrane

Product Quick Detail

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

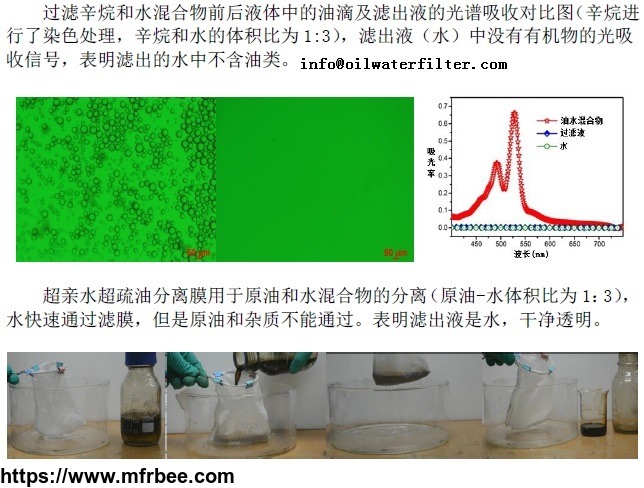

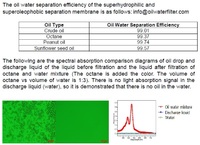

The superhydrophilic and superoleophobic separation membrane is researched and developed to separate oil, alkanes, benzene and water when oil water mixture passes it.The water quickly passes the membrane, but the oil and solid is hold by the membrane. It is suitable for the situation of more water and less oil. It helps thedischarge water to be in compliance with environmental laws and regulations or internal ISO 14001 Objectives and Targets.

Features

Independent proprietary intellectual property rights.

Superhydrophilic.

Superoleophobic.

Simple structure.

Flexible to bend.

Easy to use.

Cost effective.

Excellent quality.

Diverse applications.

Can be made to kinds of filter bags and filter cartridges.

Can be custom to meet the requirements of applications.

The water quickly passes the membrane, but the oil and solid is holdbythe membrane.

Excellent filtration effect and perfect filtration efficiencyunderthe situation of more water and less oil.

Excellenteffect and perfect efficiency to separate kinds of floating oil,oil film,light oil, heavy oil, crude oil, vegetable oil, crude benzene and water.

Long lifecycle, can be reused for more than 20 times after cleaning.

Don’t need any additive to purify water.

Don’t have any pollution and secondary pollution. The material itself can be degraded automatically, and can be burned as fuel.

Should be soaked in city water for more than 5 minutes before use.

Applications

To deoil from air for compressor.

To remove the floating oil and oil film for ballast water.

Toremove the floating oil and oil film on the surface ofwaste water in waste water treatment plant, so that it is easier to do water treatment than before.

To remove the floating oiland oil film in the waste waterpool in industrial plant to meet environmental protection standards of discharge water.

To remove and recover the oil film from produced water and reinjection water in crude oil exploration.

To remove oil film from the used cutting fluid in machine industry.

- Country: China (Mainland)

- Business Type: Manufacturer,Trading Company,Distributor/Wholesaler

- Market: Africa,Americas,Asia,Europe,European Union,Middle East,Oceania

- Founded Year: 2017

- Address: No.42, Xianghu Road, Xiaoshan District,

- Contact: Maverick Guo