Digital Auto Burst Strength Tester

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- china

- Packaging

- Packed by solid wooden case;

- Delivery

- 15 Days

Specifications

Applications:

The intelligent control algorithm gives accurate control of the burst time. Manual or automatic mode. Windows based software could analyze the test results and print, easy to operate. Different test areas can be accommodated allowing testing to corresponding standards.

Product Information:

Technical Parameters:

C. Clamping device: Φ112.8mm±0.2mm(100cm), Φ79.8±0.2mm(50cm), Φ35.7±0.2mm(10cm), Φ31.5±0.2mm(7.5cm), Φ30.5±0.2mm(7.3cm), Φ30±0.2mm;

Instrument Configurations:

- Country:

- Business Type:

- Market:

- Founded Year:

- Address:

- Contact:QIAN qian

Other products from Qinsun Instruments (Shanghai) Co., Ltd.

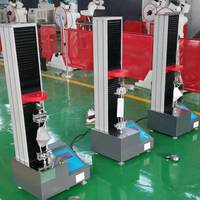

Relate products of Digital Auto Burst Strength Tester

The force required for bursting or complete rupture of the board is measured through a Digital Indicator. The bursting strength defines the materials\' quality as compared to the others. DigitalBursting Strength Tester MODEL PBD - 400 Pressure Range: 40 Kg/ cm2 Least Count : ...

Standards: GB/T7742, FZ/T60019, ISO 13938.2, NEXT TEST METHOD 22 2006 ,WOOLMARK TM29 2000,EDANA 80.3-99,ISO 2758,ASTMD 3786,JISL108 Scope of application: Digital bursting strength tester is used for the detection of woven, knitted, non-woven fabrics, paper or board about the ...

The new G229P pneumatic bursting strength tester adopts pneumatic drum explosion principle. It can quickly and accurately test the fracture strength, bursting height, bursting strength and other physical property parameters when the test material is uniformly stressed on the ...