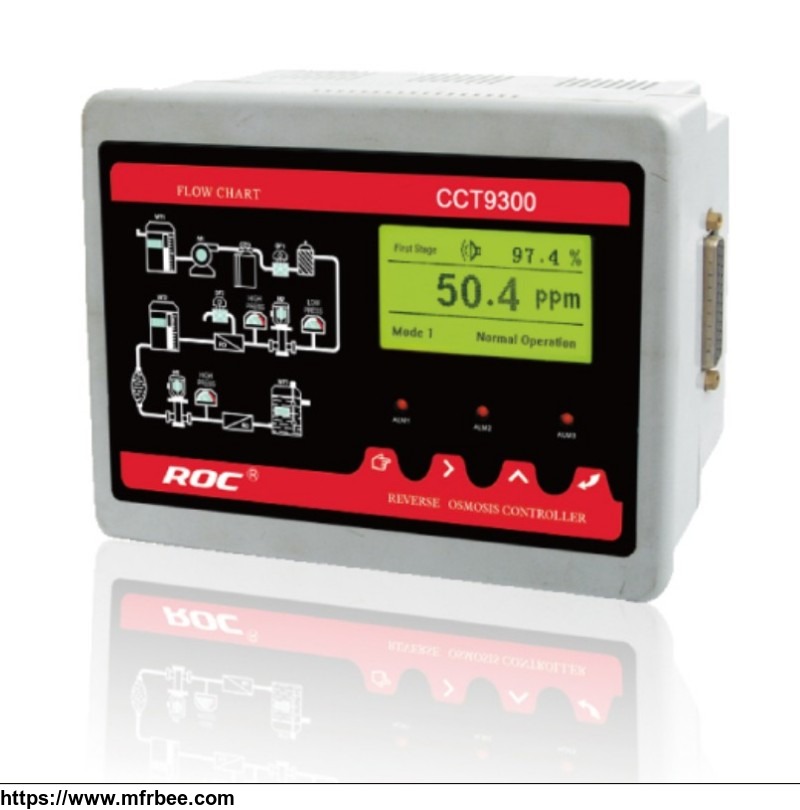

Industrial Reverse Osmosis Controlller CCT-9300

Specifications

Industrial Reverse Osmosis Controlller CCT-9300

CCT-9300 Two stage Reverse Osmosis Controller and on-line combined conductivity controller, composed of a special system for measurement and control which is made up of Reverse Osmosis PLC Controller and Conductivity Controller.

The system has the functions of automatic test, operation test, status control, display, letter hint, indicate light display and alarm in real time. with difference and operation mode which can be set by the menu, representative demands of the system operation are met. The instrument have all the advantages of PLC controller and meter for measuring water quality. Simplifying the designing and operation factors, the instrument make the hard questions easier.

The instrument adopt big screen LCD with olivine back light, open operation for setting of parameter. So all the parameters can be preset or modified more conveniently. American the latest high-speed MCU computer operation system is adopted, which can perform menu and multi-level menu in Chinese(or English).The design of the product pay much attention to the high stability, high reliability ,resistance of interference and digital operation.

The instrument can monitor , synchronously, conductivity value of headwater, first stage water output and second stage water output. Perfect 4-20mA electric current loop output and 485 communication system make it easy for long-distance communication of meter with super computer.

The instrument use rolling model display , switch of conductivity value and temperature, first-stage reverse osmosis conductivity and second-stage rate of desalination, second-stage reverse osmosis conductivity and second-stage rate of desalination; Enhanced 4+1 digit password. avoiding the illegal operation by non-employee. Indicating light are installed on the panel in patterns of flow chart, making it possible to track the operation of the system at any time. Workers can master the operation freely.

With combination of first-stage and second-stage reverse osmosis ,system managing carrying out the automatic controlling as well as self monitoring. This is applicable for industrial pure water equipment, reverse osmosis set in process of desalting of seawater .

RS485 isolated data interface, standard Modbus communication agreement(RTU), connecting with PLC, epigyny device configuration expediently, epigyny device can send reading orders. the inflow water conductivity , output water conductivity, controlling status of the relay, alarm input status and system running status, baud rate 2400,4800,9600 can be set by keyboard.

Technical Specifications:

| Reverse osmosis collecting point | Raw water tank level, middle tank level, no water protection, handle/automatic control, first stage pressurization pump low/high pressure protection, second stage pressurization pump high pressure protection, and so on. |

| Collecting input signal | direct current power supply, pull electrical digit, all terminals are isolated . |

| Reverse osmosis controlling point | feed water pump, first-grade pressurization pump, second-grade pressurization pump, inlet water valve, pretreatment valve, flushing valve,first-grade over-limit outflow valve, second-grade over-limit outflow valve. |

| Measuring collection point | raw water conductivity collect ,first-stage outlet water conductivity collect, and second-stage outlet water as well as temperature collection . |

| Measuring range | Raw water conductivity 0~20mS/cm、0~2000μS/cm(match 10cm-1or 1.0cm-1electrode) first-stage reverse osmosis conductivity 0~200μS/cm(match 1.0 cm-1 electrode) second-stage reverse osmosis conductivity 0~20μS/cm(match 0.1cm-1 electrode) |

| Power supply voltage | 24V DC (switch should be installed outside when designing) |

| Accuracy | 1.5 level |

| Output control mode | ON single contactor output |

| Load capacity of output contact | 5A/250V AC 3A/24V DC |

| Rate of renewal of connecting result | ≤1second\time |

| Operation pressure of conductance cell | 0~0.5Mpa |

| Temperature compensation | automatic temperature with 25℃ as reference temperature |

| Outline dimensions | 130×180×60mm(height×width×depth) |

| meter board hole | 122×172mm (height×width) |

| Installation | control plate panel |

- Country: China (Mainland)

- Business Type: Trading Company,Manufacturer

- Market: Asia,Europe

- Founded Year: 2003

- Address: No.8 Huifeng Road, Qiaoxi Dist.,Shijiazhuang China

- Contact: David Lee