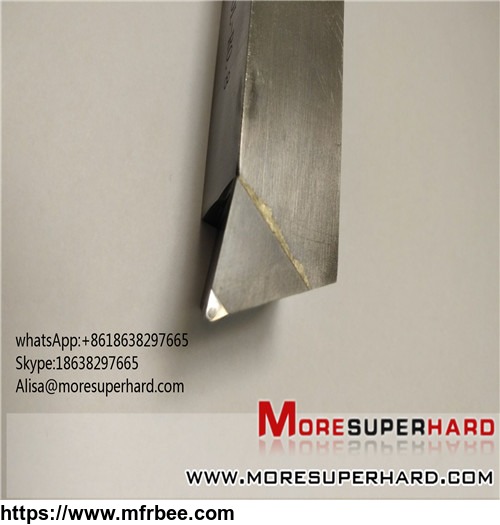

PCD grooving tools Alisa@moresuperhard.com

Product Quick Detail

- FOB Price

- USD $50.00 / Piece

- Place Of Origin

- China

- Material

- diamond

- Application Industry

- Jewelry, Automobile, Aerospace, Oil drilling, Coal mining, Metal processing

- Minimum Order

- 1

- Color

- black

- Emial

- Alisa@moresuperhard.com

- Packaging

- carton box with foam box (Gift package is available)

- Delivery

- 15 Days

Specifications

Detaials:

More Superhard grooving tools are successfully used in many automobile and engineering industries for grooving aluminum and non-ferrous and ferrous metals. With high precision and multi functional capabilities, reducing grooving time, increasing productivity and reducing through-put time with lower tooling costs.

applications of PCD grooving tools:

Grooving aluminum alloy pistons and non ferrous parts. The PCD external grooving tools are used to groove and cut various materials including copper, aluminum,copper alloy, aluminum alloy, tungsten carbide and nonmetal work pieces.

advantages of PCD grooving tools:

1.The special carbide substrate and high wear resistance of PCD material, effectively overcome easily cutting knife in theprocessing.

2.PCD grooving tools with high precision, good wear resistance.

3.The PCD ring grooving tools' precision can reach 3 -4 μm .

4.Piston is made of aluminum alloy containing more than 17% silicon , has strong wear resistance that needs more high wear resistant PCD tools to process.

5.The service Life of the welding PCD grooving tools is 10 -15 times that of carbide tools.

6.Ewag precision Manual grinding machine

7.Technical team with over 10 years experience

Materials of tool bit:

The tool bit of grooving tools uses pcd cutting blanks manufactured by Element Six (E6), DI (GE), ILJIN, SMITH, SUMITOMO and TOMEI.

Application Cases Of PCD Grooving Tools for pistons:

PCD Grooving Tools Have Sent To Iran Clients And Got A Good Feedback

If you have any questions, please contact us

WhatsApp:+8618638297665

Skype:18638297665

Alisa@moresuperhard.com

Tel:18638297665

URL:www.moresuperhard.com

- Country: China (Mainland)

- Business Type: 贸易公司

- Market:非洲,欧洲,美洲,中东

- Founded Year:2014

- Address:

- Contact:Alisa Zhang

Other products from Henan More Super Hard Products Co.,Ltd

Relate products of PCD grooving tools Alisa@moresuperhard.com

描述:PCD 镗孔工具由 PCD 毛坯 (E6) 焊接在碳化钨主体上制成。最常见的是全面 PCD 开槽工具。PCD 镗孔工具用于加工各种碳化钨滚轮。用于碳化钨滚轮开槽的 PCD 刀头。 细节 规格 PCD 镗孔和开槽刀具的应用: PCD ...

Detials 加工方式: 车削、半加工、加工 特点: PCD车刀具有使用寿命长、效率高、加工工件光亮度高等特点。 在轮毂加工过程中,使用PCD轮毂刀具对铝合金轮毂轮圈进行修复和整修。 PCD轮毂车刀应用 ...