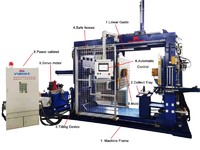

APG Clamping Machines factory

1.high quality clamping mould

2.Supply APG moulds

3.Experienced engineers

4.Long life service

volmet Electricity Technology Co.,Ltdisthe only supplier who professional produce APG

machine,apg casting machine,apg clamping machine,apg clamping machine for apg process,apg epoxy resin clamping machine ,apg equipment,apg hydraulic molding

machine,apg molding machine ,automatic injection moulding apg machine,epoxy insulators apg clamping machine,epoxy resin apg casting machine,epoxy resin apg clamping

machine,epoxy resin apg machine,epoxy resin apg molding machine,epoxy resin hydraulic forming machine,APG molds,casting mold and instrument transformer winding

machine.

|

apg machine frame

|

1 set

|

|

electric power pack

|

1 set

|

|

hydraulic power pack

|

1 set

|

|

mixing frame

|

1 set

|

|

mixing pots

|

2 sets

|

Main Technical Parameters

|

VOL-100L

|

|

Strirring power

|

Strirring Speed

|

Vacuum pump power

|

Worm gear screw jack

|

Vacuum degree

|

|

3 (kW)

|

21-118 (m/min)

|

1.1KW,2800r/min

|

0.37 (kW)

|

1.5 (mbar)

|

|

Dimension of mixer device

|

Weight of mixing device

|

Pot capacity (L)

|

Machine dimension

|

Machine weight

|

|

1900X850X1885 (mm)

|

680 (KG)

|

100L

|

910X760X1565(mm)

|

455(KG)

|

Products

1:Good product quality,fine surface finish of products without bubbles.

2:High efficiency and high automation,only need 1/2 workers operate APG machine,efficiency greatly raised but the intensity

of labor is decreased.

3:Chemical resistance,electrical insulation,strength resistance greatly improved.

|

Volmet VS Other Suppliers

|

|

Items

|

volmet

|

Other Suppliers

|

|

Set the machine start time

|

√

|

×

|

Offer electronic vacuum gauge

(For the vacuum stirring mixing device)

|

√

|

×

|

Offer thin film de-gassing, excellent vacuumize

(For the vacuum stirring mixing device)

|

√

|

×

|

|

Offer oil cycling heating surround pot, heated evenly (For the vacuum stirring mixing device)

|

√

|

×

|

|

Pressure setting and safety valve improve safety coefficient (Double insurance for the vacuum stirring mixing device )

|

√

|

×

|

|

Offer matched APG mold

|

√

|

×

|

|

Offer free APG technique training

|

√

|

×

|

Mixing machine system

The main machine+Mixing device+ Stirring rack+Hydraulic Station+ Power distribution cabinet+Oven.

APG moulding Machine adopts structure of fixed mould plate in the middle, one set of equipment can be used as two, when one side carries out clamping and injection

production, the other side can be opened to take out the product, and clean the mould, it not only cuts down the equipment cost, but also improves the production

efficiency.It has upper and lower core pulling, is suitable for small-sized bushing, contact box, post insulator, sensor, various supports, transformer,

etc.

This company produces the APG equipment has the following several advantages:

1, the only one at the same time the APG manufacturing equipment and APG pressure injection mould, equipment and mold better coordination, to ensure that product

qualification.

2, the only company with domestic transformer product testing equipment manufacturer, product compression, partial discharge test equipment, as required in our trial

production of qualified products, in the shipment.

, have rich experience of transformer production technology teacher, for your company provide free technology training, and help customers qualified products.

4, specially designed for transformer of thin film degassing mixing device, greatly improving the uniformity of mixing and pumping vacuum material.

5, Combination of equipment, moulds, as well as under the engineers constantly summarize and improve the production equipment has superior performance, high efficiency

energy saving etc.

6.By APG pressure gel molding process, greatly improving the production efficiency, increased the product surface bright and clean degree, reduce the mold cost,

reduces the labor costs of inputs.

7.We can customize machine according to customer's needs.

APG technological process includes three sections: Pre-mixing, Automatic pressure gelating and Curing.

The complete plant for APG Process need moulds, pre-mixing device, movable injection pressure vessel, hydraulic pressure gelating machine, air compressor curing oven,

etc.

volmet automatic clamping machinespermit the productivity advantages of APG systems to be fully realized. The whole system as well as the

mould are easily accessible. They can be tilted androtated around various axes. This enables the moulds to be inserted by automatic lifting devices.

The static mixer can be directly docked on to / decoupled from the filling nozzle. The short path with just a small quantity of reactive mass ensures the uniform,

homogeneous quality of the cast component and minimizes wastage of material.

Core pullers can be fitted wherever are needed.

Construction withstands rigorous continuous operation and high static loading but at the same time slim, cost-saving design.

The Volmet clamping machines can be rapidly retooled for other APG moulds.

With the Universal Clamping Machines volmet also offers a flexible modular system for customer-specific, cost-favourable design.

Starting from the basic model,huaap universal clamping machines can be enhanced and/or expanded — in accordance with the particular market and order situation — to

ever more efficient and capable systems.

Features:

Low power consumption

Less maintenance

High operation efficency standards

Abrasion resistant

Easy function

Excellent design

Robust construction

Corrosion resistant

Long life servies

|