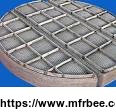

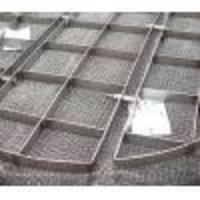

Monel 400 Demisters

Specifications

Monel 400 Demisters

Monel 400 Demisterscan reduce the residence time required to separate a given liquid droplet size thereby reducing the volume and associated cost of separator equipment. Demisters are often used where vapour quality is important in regard to entrained liquids; particularly where separator equipment costs are high (e.g., high pressure systems) or where space or weight savings are advantageous.

Compared to steel, Monel is very difficult to machine as it work-hardens very quickly. It needs to be turned and worked at slow speeds and low feed rates. It is resistant to corrosion and acids, and some alloys can withstand a fire in pure oxygen. It is commonly used in applications with highly corrosive conditions. Small additions of aluminium and titanium form an alloy (K-500) with the same corrosion resistance but with much greater strength due to gamma prime formation on aging. Monel is typically much more expensive than stainless steel.

Monel alloy 400 has a specific gravity of 8.83, an electrical conductivity of approximately 3.4% IACS, and (in the annealed state) a hardness of 65 Rockwell B

We can also make other material demisters:

- SS 304 – SS 304L – SS 316 – SS 316L mist eliminator demister

- Monel 400 – Monel 600 – Monel 800 mist eliminator demister

- Teflonmist eliminator demister

- Hostaflonmist eliminator demister

- Poly-propylenemist eliminator demister

- Inconel 625 – Inconel 825 mist eliminator demister

Knit Type Koch Divmet Yorkstyle Bulk Density kg/m3

Surface Area m2/m3

Void-age %

- 9048

9048

9030

-

9032

9001

-

-

- 9310

3260

4310

3710

4210

4120

5520

5540

- 931

326

431

371

421

-

-

333

75 80

128

144

160

173

192

320

432

815 157

800

282

535

360

377

905

2000

93.0 99.0

98.4

98.2

94.0

97.7

97.6

96.0

94.6

- Country: China (Mainland)

- Founded Year: 2010

- Contact: tong zhang