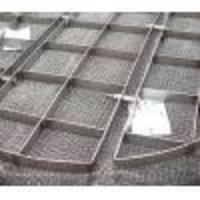

Demister pad, wire mesh demister

Specifications

Wire-meshdemister(or mist eliminator)is mainly used to separate drops of the diameter between 3μ M to 5μ M, the operating principle is showed in the fig at the right side. When the gas with liquid drops rises at a certain speed, passing through the wire mesh on the grid bar, the inertia of the rising drops make them collide with the wire and then adhere to the surface of the wire. The drops on the wire will diffuse and subside.

It makes the drops form bigger ones and then flow along the wire to the intertexture of the wire. Because the wire can be humidified, and because of the surface tension of liquid and the capillarity effect of the wire, the drops will become bigger and bigger. They will be separated and fall when their own weight exceed the resultant force of buoyancy of the rising gas and surface tension of liquid. They will flow to the device of the container in the backward position.

As long as the speed of the gas is properly controlled and with other proper condition, the efficiency of foam remove will be as high as 97% after the gas pass through wire-mesh demister. The purpose of removing foam will be achieved completely.

The characteristic of wire-mesh demister

Structure simple, weight light.

High factor of porosity, low head loss.

Great contact surface area, high removing foam ratio.

Convenience of installing, operating and repairing.

Long service life.

China standard of wire-mesh demister

HG5-1404(1405\1406)-81

The new standard units includes three installing modalities: Ascension pipe type, reduction diameter type and full diameter type. The diameters of the wire mesh demisters are ranging from about 300mm to 6400mm, and the height of the wire-mesh has two alternates: 100mm or 150mm. Only type number and required material are requested when ordering.

Standard number demonstration: HG5-1406-81-11, 304/304

It expresses wire-mesh demister: Both the grille and the wire-mesh are used stainless 304, full diameter type and up-stalling, diameter is 1600mm, height is 100mm.

HG/T21618-1998

The new standard unites the three installing modalities of ascension pipe type, reduction diameter type and full diameter type, puts forward four types of meshwork, namely SP\HP\DP and HR, expands the variety of the material to be used. It increases more types in size.

Standard number demonstration: HG/T21618 wire-mesh demister S1600-100 SP 304/304

It express wire-mesh demister: Both the grille and the wire-mesh are used stainless 304, up-stalling, diameter is 1600mm, height is 100mm, and the mesh type is SP.

HG/T21586-98 (drawer wire-mesh demister)

This standard is mainly applied in the situation in which the components of demister need clean and replace frequently. For example, the drying tower and the absorbing tower of vitriol devices. There are totally 56 types of general diameters to choose, ranging from DN300mm to DN5000mm. Only type number and material are requested when ordering. (Among these, 316L, NS-80 as well as RS-2 are materials for mesh on vitriol devices.

Standard number demonstration: HG/T21586.11-98 WME-1600-100 NS-80/Q235-A

It represents drawer wire-mesh demister: Material of the wire-mesh is NS-80, grille is carbon steel bar of which diameter is 1600mm, height is 100mm.

Other non-standard wire-mesh demister

Our company can also make a great variety of special shape wire-mesh demisters according to the clients' requirement, such as wave type, embedding type, outside-loaded type, SWD1 type, square type, rectangle type and abnormal type, etc. The height and interval of the wire-mesh demister can be altered according to the clients' demand.

Our factory will provide charts of bearing hardware and the installation charts of wire-mesh demisters to every client who choose China standard.

Material of Wire-mesh demister

Wire-mesh demisters produced in our company have three kinds according to material: Metal, nonmetal and metal knitting with nonmetal.

| material of wire mesh demister | ||

| Q235-A | Q235-A | GB343 |

| 20 | 20 | GB3206 |

| 0Cr19Ni9 | 304 | GB4240 |

| 00Cr19Ni11 | 304L | |

| 0Cr17Ni12Mo2 | 316 | |

| 0Cr17Ni14Mo2 | 316L | |

| 0Cr19Ni10Ti | 321 | |

| 0Cr19Ni13Mo3 | 317 | |

| 0Cr25Ni20 | 310 | |

| 1Cr25Ni20Si2 | 310S | |

| 00Cr20Ni25Mo4.5Cu(N08904) | 904L | |

| 0Cr23Ni13 | 309S | |

| NS-80(1Cr18Ni11Si4AlTi) | ||

| RS-2 | ||

| H68\H65\H62 | GB3110 | |

| Qsn | GB3128 | |

| N4\N6\N7\N8 | GB3120 | |

| TA2\TA3\TC3\TC4 | GB3623 | |

| PVC | ||

| PE | ||

| / | PP | |

| (F4) | PTFE | |

| (F46) | PE | |

| PFA\ETFE\PVCF etc. | ||

| (20) | Hastelloy alloy | |

| Inconel | ||

| () | Monel | |

| (F46) | PE | |

| co-knitted | S. S & Fiberglas. | |

| co-knitted | S. S & PP. PVC. F46. etc |

- Country: China (Mainland)

- Founded Year: 2010

- Contact: tong zhang