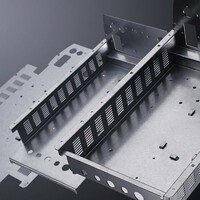

Sheet metal working metal spinning parts

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part.Spinning can be performed by hand or by a CNC lathe.

Metal spinning does not involve removal of material, as in conventional wood or metal turning, but forming (moulding) of sheet material over an existing shape.

Metal spinning ranges from an artisan's specialty to the most advantageous way to form round metal parts for commercial applications. Artisans use the process to produce architectural detail, specialty lighting, decorative household goods and urns. Commercial applications include rocket nose cones, cookware, gas cylinders, brass instrument bells, and public waste receptacles. Virtually any ductile metal may be formed, from aluminum or stainless steel, to high-strength, high-temperature alloys. The diameter and depth of formed parts are limited only by the size of the equipment available.

2. Specification

2.1. Material

Appropriate sheet metals suitable for deep drawing process, like copper, mild steel, stainless steel, aluminum.etc.

2.2. Dimension

Length or diameter up to 1200 mm; Width or diameter up to 1200 mm; Height up to 600 mm; Wall thickness up to 8mm;

2.3. Part shape

Round, square, rectangle, cone, sphere or custom shapes

2.4. Surface finish

Painting, powder coating, passivation, polishing,etc.

3. Packing way

Best suitable packing way, typical outer packing is pallet or plywood case; typical inside packing is carton box or protection film.

4. Application

Widely used in industrial fields, automobile parts, food industry,etc.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year:2014

- Address:NO.12 EAST MOZHOU ROAD, JIANGNING DISTRICT, NANJING

- Contact:Frances Cai

Other products from NANJING METALLI INDUSTRIAL CO., LIMITED

Relate products of Sheet metal working metal spinning parts

Experts in precision sheet metal fabrication. 1 unit prototyping & 1000+ production parts. We have more than decades of experience to provide custom sheet metal parts to our customers, becoming a professional custom metal parts factory. With the high skillful technology, we are ...

Sheet Metal Chassis Parts Material: Stainless steel galvanized steel electrolytic plate Thickness : 1.5mm/ 1.8mm/ 2.0mm/ 2.5mm/ 3.0mm/ 4.0 mm/ 5.0mm/ 6.0mm Processing: blanking - deburring - flanging and tapping m3- bending - black sand grain powder(This surface treatment is ...

Stamped Stainless Steel Sheet Metal Parts Sibai provides stamping processing on different metal materials, especially from steel and stainless. Sibai design and produce stamping tools, to realize complex parts. Sibai has different Tons of stamping machines. The thickness for ...