Maltose syrup processing machine

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

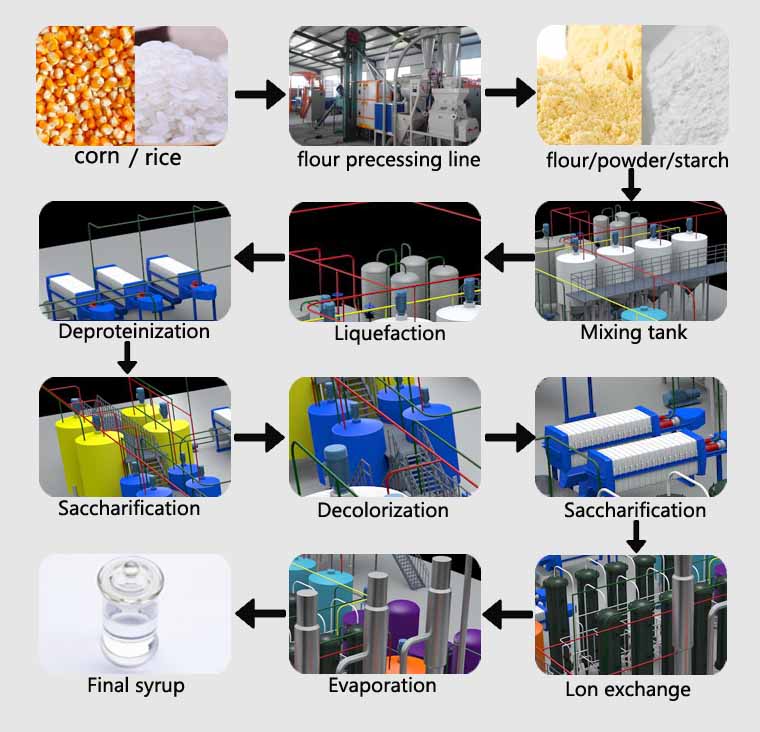

The process of transforming rice into maltose syrup and rice into maltose syrup is similar. We introduce the machine of corn to transform maltose syrup as an example.

Maltose syrup processing technology

There are 10 main process during corn flour maltose syrup production line. Here we introduce about each step of maltose syrup processing from corn flour.

Step 1: Mixing process

The mixing process is mixing the corn powder and water to get the right density slurry. Then add the enzyme and keep on the temperature for particular time to make sure corn powder absorbing water totally. The whole process shall be keep for several hours.

Step 2: The liquefaction process

The liquefaction process is convert the starch inside of corn powder into liquid dextrin. The corn powder slurry will be sprayed at high temperature by jet cooker. With the aid of enzyme , the starch will be converted into liquid dextrin quickly.

Step 3: The deproteinization process

The deproteinization process is separate the corn protein and other solid impurity from liquid dextrin by filter press. The liquid dextrin will be pumped to next process, the corn protein feed will be left for sale. The corn protein feed yield is about 18% of the corn powder.

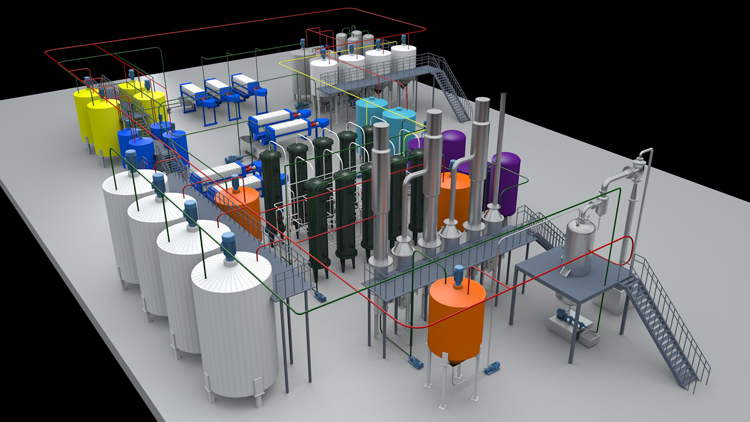

Maltose syrup production machine

Step 4: The saccharification process

The saccharification process is convert the liquid dextrin into required DE value maltose syrup with the aid of saccharification enzyme in the tank. This process should be run under specific temperature for some hours. This process is get the crude and yellow color maltose syrup.

Step 5: The decolorization process

The decolorization process is removing the color of the maltose syrup by activated carbon. The maltose syrup which reached required DE will be pumped from saccharification tank into the decolorization tank, mixed with activated carbon at proper temperature.

Step 6: The decarburization process

The decarburization process is separating the activated carbon from the maltose syrup by filter press to get clear maltose syrup. The maltose syrup will flow into the slot and the transfer tank for next step. The activated carbon will be left.

Step 7: The Ion exchange process

The Ion exchange process is using the resin to remove the tiny foreign items and bad odor to get high quality pure maltose syrup. The resin need regeneration by acid and alkali washing after working for some days.

Step 8: The evaporation process

The evaporation process is evaporate the water inside the glucose syrup to increase the DS of maltose syrup. Usually it need multi-effect evaporator work together with the single effect evaporator.

Step 9: Final product storage

The maltose syrup which reach the required DS in the evaporation process will be pumped into final product storage tanks for storage. The final product tank can keep the maltose syrup purity before transportation.

Step 10: Lab

The Lab equipment will be used to check the quality and the technical parameter of the product during all the production process.

Maltose syrup processing machine

The maltose syrup production process raw material can be rice,corn,maize,and so on.

Our company focus on liquid syrup processing equipment manufacturing for more than 24 years. We supply equipment to all over the world and received unanimous praises from our clients.

- Country: China (Mainland)

- Business Type: 选择一个

- Market:

- Founded Year:1994

- Address:

- Contact:zhang xiansheng

Other products from Kaifeng sida agricultural products equipment co. LTD

Relate products of Maltose syrup processing machine

Wet Processing Equipment for All Chemical Etching Purposes Wet Chemical Etching Machine Wet Processing Equipment – wet etching machine The etching machine is used to spray chemical solution to a copper-clad laminator, aluminum substrate, or stainless steel plate, the exposed ...

CNC Machining or Not: Cnc Machining Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping Material Capabilities: Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, ...

CNC Machining or Not: Cnc Machining Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Wire EDM Material Capabilities: Aluminum, Brass, Bronze, Stainless steel, Steel Alloys, carbon fiber,plastic,glass,rubber,wood etc. ...