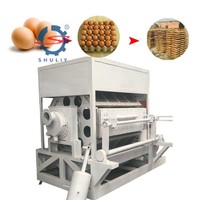

Egg tray production equipment

Specifications

The selection of the material for the egg tray machine to make the pulp is to use old paper, waste cardboard boxes, waste printed materials, and scraps from various paper product factories as raw materials. Then, it is vacuum-adsorbed on a special metal mold to form a wet green product, and then the wet green product is shaped by dry media and press.

The hydraulic pulper disintegrates waste newspapers, corrugated packaging, and other waste materials at the corners. The strip-shaped impurities such as bundles are wrapped around the winch to be unloaded and removed. The heavy-duty trap at the bottom of the hydraulic pulper is regularly discharged to eliminate heavy dirt. The disintegrated coarse pulp is stored in a pulp tank and sent to a Gaoning slag remover through a pulp pump. The good pulp is sent to a reciprocating fiber separator for further screening, separation, and disintegration.

Egg tray machine

The roll-type pulp molding machine of egg tray production equipment has introduced advanced technology development. Because of its excellent performance characteristics, it has been well received by customers and recognized by society. The main body of the equipment is made of stainless steel, and the other parts are made of high-quality accessories. We have developed automatic counting, automatic stacking, and automatic packing systems. This pulp molding machine has the characteristics of high productivity, low failure rate, and low energy consumption. Pulp molding systems use a variety of waste paper to produce high-quality molded fiber products. Changing different molds can produce egg trays, vegetable trays, fruit trays, canned trays, seed trays, etc.

Egg tray production line

The large octagonal rotary forming machine for the egg tray machine has a total of eight suction surfaces, forming an octahedron. The octahedron rotates intermittently above the paddle. Four suction molds are installed on each suction surface, and four egg trays can be produced with each rotation. The suction mold is suction-molded by means of back suction. The thickness of the egg tray is uniform, the density is high, and the strength is good. The wet blank transfer is done by a robot. The rotary molding machine is generally matched with the crawler conveyor automatic drying system, and the output can reach more than 4000 pieces per hour.

The drying system of this machine adopts a 6-layer metal drying line, which is characterized by saving 30% energy and reducing floor space. Fuel can use natural gas, diesel, coal.

website:https://www.eggtraymaking.com/egg-tray-making-machine/

1-Pulping system: hydraulic pulper, pulp pump, vibrating screen, refiner, mixer, etc.

2-Forming system: drum forming machine, mold, air compressor, air compressor tank, vacuum pump, vacuum tank, high-pressure water pump, steam-water separation pump, etc.

3-drying system: hot air fan, dehumidifying fan, dehumidifying pipe, burner, combustion chamber, conveyor belt, chain, etc.

4-Packaging system: stacker, compaction equipment, packer, etc.

- Country: China (Mainland)

- Founded Year: 2011

- Contact: allen guo