Aluminum Drill Pipe

Specifications

Quick Information

- Brand Name:Saigao

- Place of Origin:China

- :

Description

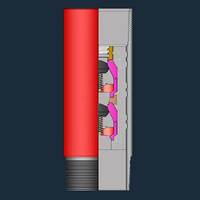

Aluminum Drill Pipe

Overview

Aluminum drill pipe has the advantage of low density, high strength, corrosion and fatigue resistance, good processing performance and excellent low temperature toughness. It is a promising technique to solve the drilling problems arising from complex working conditions of the deep and super deep well, horizontal well, extended reach well, sour well and offshore well etc. As it can improve the efficiency and safety of drilling, the technique of aluminum drill pipe is significant important. The feature and process of aluminum drill pipe in recent years are reviewed. Some proposals for the application of aluminum drill pipe in China oil and gas industry are also provided.

Features

Aluminum drill pipe biggest advantage lies in the light weight. The strength-to-mass ratio of aluminum is 1.5-2 times that of steel. For deep wells above 8000 meters, the conventional steel drill pipe with outer diameter of 139mm and wall thickness of 10.54mm weighs about 300 tons. The weight of aluminum drill pipe only needs 100 tons, so the aluminum drill pipe shows a stronger drilling depth than the steel drill pipe.

Anti-corrosion, aluminum alloy drill pipe can effectively prevent corrosion of H2S and CO2. The chemical properties of aluminum and its alloying elements are relatively active. When reacted with oxygen, it forms a stable oxide film on the surface to prevent further reaction with the surrounding environment. Laboratory test results show that the aluminum alloy drill pipe does not corrode in the saturated H2S solution and CO2 solution for a long time. After practical application, the aluminum alloy drill pipe can effectively prevent the corrosion of H2S and CO2 at any temperature.

Anti-fatigue, alternating bending and dynamic stress resistance is three times that of steel. The aluminum alloy drill pipe has a small elastic modulus. When an aluminum alloy drill pipe is used in a directional well and a horizontal well with a large curvature, the friction between the drill string and the open hole section and the casing section is reduced, and the aluminum alloy drill pipe has good resistance. The bending load performance is more suitable for directional wells and horizontal wells with large curvature, and the maximum horizontal section can reach 1000m.

The aluminum alloy drill pipe has non-magnetic properties. Steel-free joints Aluminum alloy drill rods have similar non-magnetic properties to nickel-cobalt alloys, which is advantageous for magnetic logging.

Application

With the development of oil and gas exploration to deep wells, ultra-deep wells, directional wells, horizontal wells, H2S and CO2 oil and gas wells, marine wells and other complex wells, it is inevitable to study drilling tools suitable for complex well conditions. The analysis introduces the significant advantages of aluminum alloy drill pipe in improving drilling depth, corrosion resistance, reducing hook load and directional wells and horizontal well drilling operations, and the application prospect of aluminum alloy drill pipe.

Packaging & Delivery

- Packing :customed

- Delivery Lead Time :7-15days

- Supply Ability :1000pcs/month

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2008

- Address:Zhongrun Century Center, No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

- Contact:Rex Liu