CNC Turning Machined Aluminum Anodized Mechanical Parts Manufacture

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

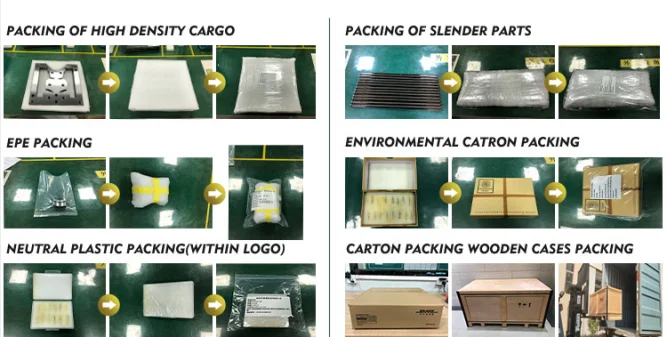

- Packaging

- 1.Coating oiling to form a protective coating against rust, corrosion, etc 2.Packed with pearl cotton to shake proof 3.Packed in

- Delivery

- 15 Days

Specifications

| Machining Capacity | CNC Turning Machining Range | φ1mm ~ 450mm x 1000mm |

| CNC Milling Machining Range | 800mm x 1500mm x 700mm | |

| CNC Stamping Machining Range | 1.2m x 0.72m (maximum weight: 320T) | |

| Laser Cutting Machining Range | 800mm x 600mm (Tolerance: ≤±0.01) | |

| Product Name | CNC Turning Machined Aluminum Anodized Mechanical Parts Manufactured in Shenzhen | |

| Surface Treatment | Anodizing, Brushing, Nickel-Plated, Zinc Plated, Galvanized, Polishing, Blackened, Powder Coating, Sandblasting, Laser Marking, etc.. | |

| Materials | Stainless Steel | SS201,301, 304, 316, 17-4PH, SS303, SS304, SS316, etc. |

| Steel | Q235, 20#, 45#, 40cr, 416 Stainless iron, etc. | |

| Brass | H59, H68, H80, H90 | |

| Bronze | C51000, C52100, C54400, etc. | |

| Aluminum | 5000 Series, 6000 Series, 7000 Series, etc. | |

| Plastic | ABS, PC, POM, Delrin, Nylon, Teflon, PP, etc. | |

| Detecting Instrument | CMM, Projection, Calipers, Micro caliper, Thread Micro caliper, Pin gauge, Caliper gauge, Pass meter, etc. | |

| Packages | Standard Export Protective Packing, suitable for various transportation; Or personalized as per customer's request. | |

| CAD Format | IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

Q. Are you trading company or manufacturer?

We are manufacturer Located in developing industry city of Dongguan Guangdong China.

Q: How can I get a sample ?

A: Customer can get a sample by sending 2D/3D/PDF drawing .

UPS, OCS, EXPRESS, DHL, FEDEX are available for shipment.

Q: What’s your lead time ?

A: 7-15 days normally, depends on the quantity and complexity

Q: What information should I provide to get a quotation ?

A: Material, quantity, dimension, tolerance; CAD drawing will be best if convenient.

Q: What about after sale service?

A: Spare parts which is non-man made damage will be offered replacement for free within 90 days after shipment, and you can contact us any time if need help.

Q: How about your quality control?

A: 1. Every processing technician

2. After the completion of processing, parts will be transferred to the QC department for full dimension inspection.

3. Double-check before packing to make sure no defective products will be released.

Q: Do you have the surface finishing capability?

A: Yes, and divided into the following sections

1. Grain surface treatment --- polishing, fire pattern, erosion, sand blasting

2. Electroplating treatment -- -nickel plating, zinc plating, chrome plating, titanium plating, chrome plating , flash chrome plating.

3. Nano coatings - TIN, TICN, DLC, TIAIN, CrAIN, CrN

- Country: China (Mainland)

- Founded Year: 2007

- Address: No.62, Jinghai East Road, Shatou District, Changan Town, Dongguan City, Guangdong Province, China

- Contact: Alisa chen