AOI PCB Defect offline / online Detecting Equipment

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

- Min Width/ Line Space

- 2/2 mil

- Max Capacity ( Offline )

- 600 panels / h

- Max Capacity ( Online )

- 500 panels / h

- Board Size

- 12"×12"-26"×30"

- Board Thickness

- 0.05mm-5.0mm

- Packaging

- 1 set each carton

- Delivery

- in 90 days

Specifications

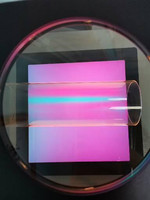

PCB Defect offline / online Detecting Equipment

(Ref :AOI-PCB-R)

Equipment Application

This device is mostly used to detect various defectson the PCB inner layer and outer layer board,such as

short/open circuit, line width/ line distancetolerance, bump/ recess, pinhole,residualcopper , scratch, hole plugs, hole, size and position errors, etc.

Application Area

Applicable to ordinary FR4 , high-frequency white board ,Teflon board , ceramic board and other hard board materials.

Equipment Features

1. Simultaneous detection of both front and back sides is completed at one loading ;

2. Combine high-resolution TDI line-array cameras with high brightness LED line sources with a variety of lighting methods for optical image contrast ;

3. The automatic loading , unloading machine and the AOI machine are flexibly combined to meet offline or online production requirements;

4. Create a new product number offline and replace the product number without downtime;

5. More than 4 times the production capacity of the traditional offline AOI , which greatly saves labor costs ;

6. Defect big data integration analysis guides the pre-process improvement process and improves yield;

7. Save/ display surface defect images and locations in real time ;

8. The system automatically counts and analyze the defect data to generate a report for reference ;

9. With AI intelligent automatic false point filtering function, reducing human review ;

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: G20,Americas,Europe,Middle East

- Founded Year: 2008

- Address: NO. 189 , Zhangji Road , Eocnomic Development Zone

- Contact: Jesse Cheng