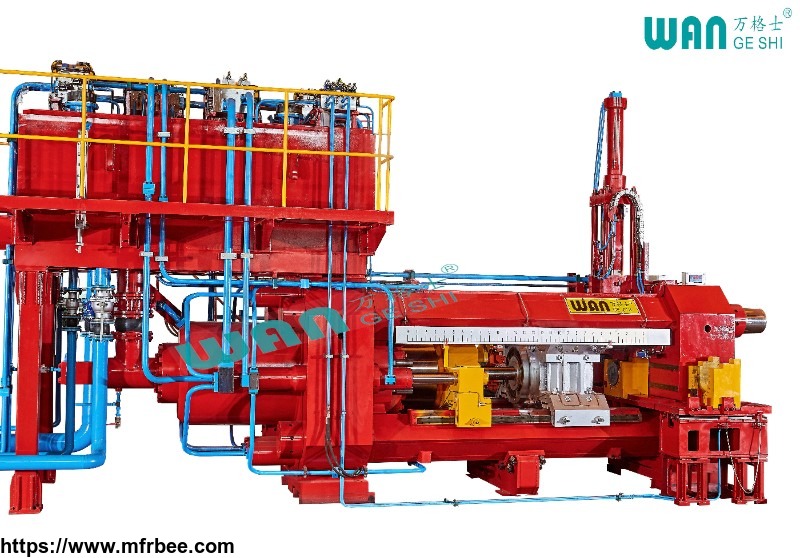

aluminium extrusion press

Product Quick Detail

- FOB Price

- USD $650,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- stand export pakage

- Delivery

- 30Days

Specifications

The horizontal single-action short-stroke rear-loading aluminum extrusion press (left type) adopts a horizontal three-beam four-column pre-stressed combined frame structure, a forward extrusion method for short-stroke loading, direct drive by an oil pump, and advanced electro-hydraulic control Components and systems, as well as complete mechanized auxiliary equipment, adopt PLC and computer two-level control, so that the speed, position and pressure of the press can be accurately controlled. The main technology adopted reflects the advanced technology level of the extrusion press. As a leader in China's aluminum profile industry, this model is independently developed by Wanges with strong R&D capabilities and is the most advanced extrusion press production line in China.

1. Host part:

*Structural design adopts3DFEMtechnology to analyze the stress, displacement,temperature, etc. of the frame,cylinder, etc., and the structure is more optimized and reasonable

*ultrasonic detection treatmentfor the main components such as the main cylinder, beam,ram stem...

*The main plunger is made of chilled cast iron, and the surface of the piston rod is finely ground and plated with hard chrome, with low roughness.

*The advanced front beam assembly is equipped with quick mold shifting and mold changing device, which is convenient for operation and maintenance.

*The flat guide rail structure can adjust the center of the movable beam, making it easier to squeeze the center of the calibration machine.

2. Hydraulic part:

﹡Pumping station adopts integrated design and optimized combination of the latest electro-hydraulic proportional pumps to meet the pressure requirements of the extruder. Each pump works independently without interfering with each other. Computer on-line control and seismic design can greatly reduce the failure rate

﹡The hydraulic system is divided into a combination of centralized lubrication and decentralized lubrication, ensuring excellent lubrication performance

*The operating system consists of an integrated control valve block) and is equipped with a pressure sensor to enable the system to realize speed regulation, pressure regulation and constant speed extrusion, meeting the requirements of special extrusion processes. The high-pressure part adopts the imported seal, with less oil leakage.

3. Electronic control part:

*Using upper industrial control computer and PLC dual-level control, each part of the extruder is equipped with communication capabilities, and the process is real-time controllable

*The operation panel is set to manual, semi-automatic/automatic, reflecting the humanized design concept.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Asia,Middle East,European Union

- Founded Year: 2005

- Address: hengang industry zone Nahai district

- Contact: jk louis