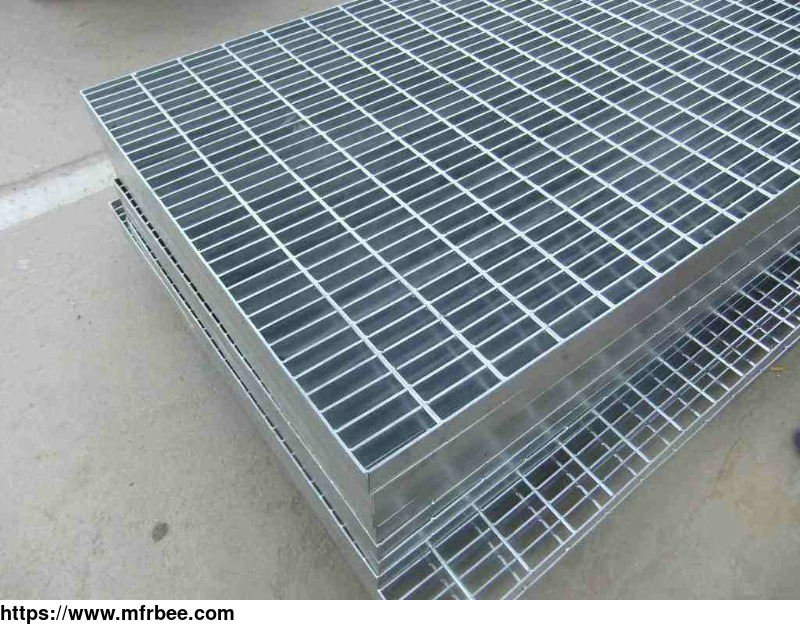

Heavy Duty Expanded Steel Gratings

Specifications

Expanded Metal Structural Steel Grating Floor Plates for Stair Tread and Decking Construction. Available in Oblong Diamond, Reverse Diamond and Hexagonal Holes.

Expanded metal grating is the most practical and economical way to assure strength, safety, and a non-skid flooring surface.

Expanded Steel Grating offers four advantages over welded steel bar gratings:

First, Expanded grate is made of one continuous piece of material yielding a greater strength to weight ratio. Second, Expanded Metal Grating Floor has no welded parts, its flooring surface is naturally skid proof without further processing. Thirdly, the pattern and openings of Expanded Grating provide a wider range of load capacity flooring to meet exact requirements. Fourth, Expanded metal grating processed from same material as bar grating costs less for your project.

This metal grating offers ease of fabrication, economy, strength, safety in industrial platform and stair tread decking construction. Processed from different metal materials including carbon steel, stainless steel and aluminum, Expanded metal grating is ideal for use as walkway and tread plates fencing, plant runways, working platforms, and catwalks. It can be supplied in light and heavy loading type. Easily cut into irregular shapes and can be installed quickly by welding or bolting.

General Tech Information:

Grating Patterns: Diamond, triangle, scale hole, etc. Expanded Metal can be processed in different opening shapes, typically as: standard rhombic shape; heavy type Tortoise-shaped; flattened; and some special shapes or designs.

Specification: thickness:0.5mm-8mm

Hole width: 2.5mm-50mm

Hole length: 4.5mm-100mm

Openness: 0.5mm-8mm

Heavy Type Hexagonal Shaped Expanded Metal, Tortoise-shaped Expanded Steel Sheet Mesh, Also Known as Raised Metal Mesh:

A kind of reinforced sheet compared with the regular diamond shaped expanded metal products.

Heavy type is ideal for uses in plants, ship-making, mineral sifting, flooring, grating, groove cover, conveying, side passages for conveyors and cranes, fences and decoration of buildings.

Material types available: Stainless steel, galvanized or plain steel.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,Asia,Emerging Markets,Europe,European Union,G20,Middle East,Oceania

- Founded Year: 2010

- Address: No.33, Lingyuan Street, Anping, China

- Contact: Gong Jianrang