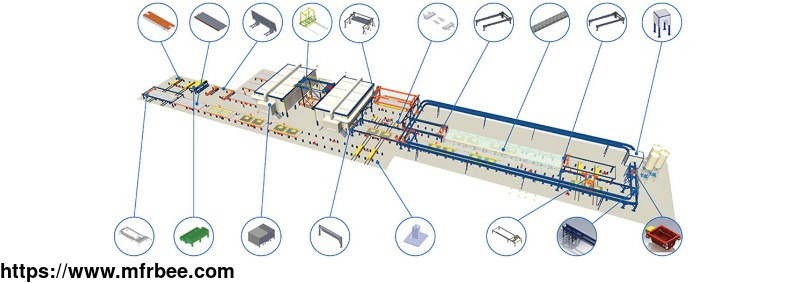

Precast Concrete Panel Production Line

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Zhejiang, China

- Packaging

- wooden packing or naked

- Delivery

- 2 months

Specifications

As the main component in precast concrete components, the assembly part, connection, combination of cast-in-place reinforced Concrete structure, PC component based on component processing unit

factory production of finished Concrete members.

One machine can not only produce one size, it depends on the machine designing.

The advantages and characteristics of Precast Concrete Panel Production Line:

1. When making precast concrete panels, it can reduce resources, energy consumption and environmental pollution.

2. It can improve the quality of building product, engineering and safety performance (seismic resistance).

3. Speed up the schedule of construction and shorten the construction cycle.

4. Reduce labor intensity and labor cost, it is the only way to transform and upgrading of Chinese construction industry.

Main Technical Parameters Of Precast Concrete Production Line

Item Parameters

Model platform size (L x W x H) 10000x3500x375mm

Precast slab maximum size (L x W) 9500x3250mm

Precast slab thickness Laminate slab 50-80mm, solid wall 100-300mm

Curing chamber precast slab number 40

The production line floor space About 3000-5000 square meter

Process Flow Of Precast Concrete Panel Production Line

Model platform, side model cleaning oil——The robot side model placement——Rebar mesh placement——Rebar truss placement——Rebar placement and tying——Concrete

placement——Galling——Thick——Maintain——Laminate——Laminate oblique discharge——Laminated wall——1800 turnover——Concrete placement——Laminated wall assemble, thick——Maintain——Oblique discharge

With 53 years' experience, Jinggong is specialized in manufacturing high-quality sandwich panel machine line, feel free to contact!

now!

- Country: China (Mainland)

- Address: #1809,Jianhu Rd, Kexi Industrial Area, Keqiao, Shaoxing, Zhejiang, China

- Contact: jinggong .com