Aluminium Window Profiles

Product Quick Detail

- Minimum Order

- 20

- Place Of Origin

- Shenzhen, Guangdong Province, China

- Packaging

- Protective Film insdie, Shrink Film or Kraft Paper outsdie

- Delivery

- 25 days

Specifications

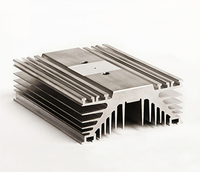

Aluminium Window Profiles

Aluminium window extrusions and doors are the most common products in architectural aluminium extrusions. In order to meet the special requirements of different customers, as an aluminum profile

company, Otalum has developed a wide range of window and door systems, including aluminium sliding windows, aluminum casement windows, aluminium tilt and turn windows, top hung sliding aluminium

windows, aluminium casement doors, etc. At here, you can easily save your time and money for cutting new dies.

If the existing products are not suitable for your special purpose, our experienced engineers can help you to design your own custom aluminium extrusions and realize it.

Aluminum extrusions from our architectural systems are available in a variety of finishes which contain mill finish, clear anodized aluminum including 2-step electrolytic anodizing, powder coating,

PVDF painting and wood-gram finish. As a mature aluminium extrusions manufacturer, Otalum also offers aluminium extrusion fabrication services on eligible inquiries.

Features of aluminium sliding window profile

Alloy Standard Surface Treatment Further Process Certificate

6005 T5/T6, 6060 T5/T6, 6061 T4/T6, 6063 T5/T6, 6463 T5/T6, 6082 T5/T6, etc. GB 5237-2008, JISH, AAMA, GB, BS, En Mill finish, Powder Coating, Anodizing, Wooden grain, Electrophoresis, PVDF

Painting, Sanding blasting, Polishing, etc. Drilling, Bending, Welding, Precise cutting, Punching, Fabrication of finished products, etc. CE, DNV, TUV, ISO9001

Why choose aluminium profiles for windows and doors

Aluminum window frames are cost-effective, sturdy and durable, while at the same time having functionality and versatility as well as a stylish modern style.

Aluminum window profiles provide highly durable and cost-effective solutions for residential and commercial buildings. They require almost no maintenance, can be used for life, will not rust, and

even have a high corrosion resistance limit.

Aluminum window profiles can be provided in standard sizes, and can also be manufactured in customized sizes and styles to meet your specific requirements.

It is also nice to know that your aluminum alloy window frame can be equipped with various types of functional glass. This includes safety protective glass, aesthetic glass, soundproof glass,

fireproof glass and bulletproof glass. They can also be double-glazed to provide higher energy efficiency, better acoustics and many other benefits, bringing comfort and security to your house.

The Production Process of Aluminum Window Profile

1. Ingot casting

The process contains the ingredients, melting, casting, homogenization. This is the main process of certain chemical composition and size of the ingot.

2. Extrusion

Extrusion includes an automatic production line composed of ingot heating, extrusion, cooling, straightening, cutting and other processes.

The ingot heating temperature is controlled at 400℃~520℃, too high or too low will directly affect the extrusion.

3. Heat treatment

Through different systems for quenching and aging treatment to obtain the mechanical properties of the profile. Aluminum profile aluminum windows provide materials in RCS state, that is, high

temperature heat treatment and rapid cooling are performed after molding and artificial aging.

4. Surface treatment

The most common steps are anodizing, electrophoresis, powder coatings and fluorocarbon coatings so that the surface can have different colors and good appearance. Surface treatment can enhance the

aesthetic appearance of the profile and prolong the service life of the aluminum window profile.

- Country: China (Mainland)

- Address: Room 3/22, COFCO Group Center, Baoan District, Shenzhen, Guangdong Province, China

- Contact: Otalum