R-PLANE (1-102) SAPPHIRE WAFERS

Product Quick Detail

- FOB Price

- USD $10.00 / Piece

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

R plane sapphire wafers are preferred for the hetero-epitaxial deposition of silicon used in microelectronic IC applications. R plane is the non-polar plane of sapphire. So the different positions

of R-plane in sapphire devices, the mechanical, thermal, electrical and optical properties of sapphire devices will vary greatly, which will also affect the subsequent processing performance,

processing efficiency and processing yield of sapphire devices.

In order to make the crystal structure of sapphire ingot and subsequent sapphire products consistent, the more common method is to process an A-direction surface on the sapphire ingot as the flat

orientation of the polished sapphire wafer (subsequent sapphire products), so that the R-direction position of sapphire ingot and the wafer is consistent.

Specifications of R-Plane (1-102) Sapphire Wafers

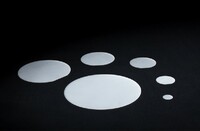

Item 2 -inch R-plane(1-102) 430μm Sapphire Wafers

Crystal Materials 99,999%, High Purity, Monocrystalline Al2O3

Grade Prime, Epi-Ready

Surface Orientation R-plane(1-102)

Diameter 50.8 mm +/- 0.1 mm

Thickness 430 μm +/- 25 μm

Primary Flat Orientation 45 +/- 1deg. counter-clockwise from C-axis projection on R-plane

Primary Flat Length 16.0 mm +/- 1.0 mm

Single Side Polished Front Surface Epi-polished, Ra < 0.5 nm (by AFM)

(SSP) Back Surface Fine ground, Ra = 0.8 μm to 1.2 μm

Double Side Polished Front Surface Epi-polished, Ra < 0.5 nm (by AFM)

(DSP) Back Surface Epi-polished, Ra < 0.5 nm (by AFM)

TTV < 10 μm

BOW < 10 μm

WARP < 10 μm

Cleaning / Packaging Class 100 cleanroom cleaning and vacuum packaging,

25 pieces in one cassette packaging or single piece packaging.

Note: Custom sapphire wafers with any orientation and any thickness can be provided.

CRYSCORE OPTOELECTRONIC LIMITED has been a professional manufacturer specialized in high-quality sapphire wafers and optical windows since 2008. We provide optical sapphire, sapphire rod, sapphire

ingot and etc. Want to know more? Please contact us.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:

- Address:No. 49, Jiefang East Road, Shanyang District, JIAOZUO 454000, HENAN, CHINA

- Contact:cry score