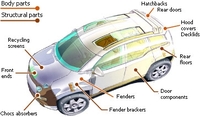

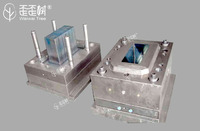

SMC Automotive Molding, Car Mould

Product Quick Detail

- Place Of Origin

- zhengjiang, China.

- FOB Price

- USD $100.00 / Piece

- Minimum Order

- 1

- Packaging

- wooden box

- Delivery

- 10 days - 2 months

Specifications

Cars, buses, trucks, transport and special vehicles

• Weight:

Parts made from sheet molding compound (automotive smc) are typically 25-35% lighter than steel parts and aluminum products of the same strength. The stroke is increased and the fuel consumption is

greatly reduced.

• Stable shape:

SMC's thermal expansion coefficient, CLTE, is low enough to withstand engine temperatures and summer temperatures, making it suitable for automotive panel covers, engine covers and roof panels.

• Surface treatment:

SMC body panels have excellent surface quality, are as easy to paint as traditional steel panels, and have a better texture.

• Production cycle:

SMC automotive is highly malleable, greatly reducing the number of components required for assembly, and thermoset materials reduce design and production time.

• Safety:

SMC has a strong insulation effect, 1mm can withstand tens of thousands of volts, and solves the insulation requirements in the automotive field.

• Durability:

SMC's superior UV protection, aging resistance, acid and alkali resistance, waterproof and moisture resistance, greatly improve the service life.

Aobang provide bmc composite, bmc molding, automotive smc moulding and etc. Contact us to know more.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Africa,Americas,Asia,Emerging Markets,Europe,G20,Middle East,Oceania

- Founded Year:313218

- Address:No.62,zhidailang,sha village,luoshe town, deqing,huzhou city, zhengjiang, China.

- Contact:Coffee Tu

Other products from ZHEJIANG AOBANG TECHNOLOGY CO.,LTD

Relate products of SMC Automotive Molding, Car Mould

SMC Automotive Molding, Car Mould

SMC Automotive Molding, Car Mould Cars, buses, trucks, transport and special vehicles • Weight: Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same strength. The stroke is increased and the fuel ...

SMC Automotive Molding, Car Mould

Cars, buses, trucks, transport and special vehicles • Weight: Parts made from sheet molding compound (automotive smc) are typically 25-35% lighter than steel parts and aluminum products of the same strength. The stroke is increased and the fuel consumption is greatly reduced. ...