BKNET-101 Automatic Eddy Current Testing

Specifications

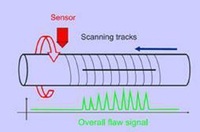

The eddy current testing (BKNET-101) is a fully automated eddy current inspection system that uses large-scale imported integrated circuits combined with advanced eddy current technology,

photoelectric technology and microcomputer control.

With a beautifully designed mechanical transmission, a complete mechatronic system is formed, and the software written by the WINDOWS operation platform makes the instrument easier and smarter to

use. The instrument has stable and reliable performance, a high degree of automation and fast detection speed. It is designed for high-speed detection of eddy current testing equipment for off-line

and on-line flaw detection of metal pipes, rods and wires.

BKNET-101 Automatic Eddy Current Testing Brief Introduction

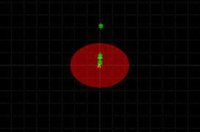

BKNET-101 eddy current flaw detector can quickly detect surface cracks, dark cracks, air holes, inclusions and opening cracks of various metal pipes, rods and wires with high detection sensitivity.

BKNET-101 eddy current flaw detector has a testing frequency range of 100Hz-1MHz. It can meet the testing requirements of various metal pipe diameters, a variety of unique alarm modes, fast

automatic electronic digital balance and full digital design.

Therefore, a standard testing procedure can be established in the instrument, which is convenient for users to call when changing materials of different specifications. At the same time, 24 hours

of real-time storage of test data, real-time detection is based, to ensure that the review of 0 defects.

As one of ultrasonic testing equipment manufacturers, we can offer types of ndt testing products for sale, if you have needs, please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Contact: bkneddy .com