2k injection molding is one type of injection mold. It is also named as two shot molding, double shot molding, double-color mold, Multi-material, or multi-component injection mold. 2k injection

molding consists of two different plastic materials and colors.

With over 15 years mold making experience, we also specialized in making 2k plastic injection moulding. Here we always have a professional team who can help you make assessments and build personal

2k injection services project solutions for you at any time. Based on your part design, we are able to provide the best price 2k injection services solution with high-quality products. Rotary

Platen Two Shot Molding and Core Toggle Two Shot Molding are our main 2k injection services. Affordable prices and quick lead time are our competitive advantage for 2K injection molding.

What is 2K Molding?

2K injection molding, also named a double injection, two-color injection molding, or 2 shot molding, 2k injection molding process used to produce molded parts from two different materials with two

colors.

As the 2K moulding factories, we operate 2K injection molding at one machine and perform two injections in one cycle. For the first cycle, plastic material is injected into a mold. Then rotated

automatically and mix another property of plastic which was injected into the mold by the second nozzle.

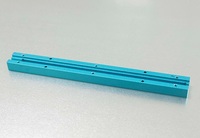

2K injection molding integrates two different grad materials like hard and soft material to make a perfect combination with production. Two color injection molding is widely used in a variety of

industries and it also allows for using clear plastics, colored patterns, and new style designs which help to make functionality products and reach marketplace value.

2K Mold Design

2K mold design is a pivotal factor for molding success. Followings are factors that will make an influence 2k molding: dimensioning and location of the sprue gates, dimensioning of shear edges,

flow aids, cooling and ejector techniques, etc. Here at Packson 2k moulding factories, we keep making good 2K mold designs and we are committed to making durable mold that is highly efficient

operating and easy to make maintenance and molding production.

The followings are the points that we need to consider during 2K mold design:

Shrinkage of plastic material

Wall thickness

Cavity Numbers

Plastic material flow systems-Runner and Gate

Cooling system for around cavity and core

Ejection System

Air venting

Applications of 2K Injection Moulding

2K injection molding is perfect for combinations of hard and soft plastics and also if you want to process 2 colors of plastic in one product.

2K injection molding is a good way for you if you want to combine two different materials like hard material and soft material into one product by injection molding processing. We create full

products in 2 steps by two color injection molding. The most common example made by 2K injection molding is bicycle handlebar, automotive button, toothbrushes with hard handle and soft handle

piece, medical diagnosis machine control button, etc.

2K Molding Design Guide

The 2K injection molding allows us to integrate multiple properties into one product: for instance, layered products, combinations of hard and soft plastic for making different color combinations.

The 2K injection molding allows us to combine two different properties of the material with hard and soft plastic for making two different colors.

Advantages Of 2K Injection Molding:

One-stop finished part without secondary processing and assembly steps

Excellent adhesion to the plastic part

Quick cycle times

The high degree of automation

High efficiency

Stable molding processes

Low-cost molding

As one of the most professional 2k molding factories, Packson Mold provides custom molding services, lsr molding and etc. We have amassed considerable experience and understanding of the practical

possibilities in this field. Contact us to know more.