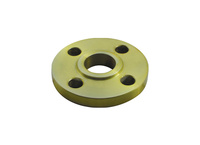

Forged steel pipe fittings are made of A105 (carbon steel), stainless steel or nickel alloy. Forging steel is a process that creates very durable fittings. These fittings are used for connecting

pipes, pumps, valves & other equipments in the pipeline system. They are thicker, heavier and are intended for heavy industrial use. Forged steel fittings are available in 2000#, 3000#, and 6000#

pressure class. These fittings are more common in 3000# and 6000# (90% of the time).

Different Types of Forged Steel Pipe Fittings

Reducing Hex. Nipple

Straight Hex. Nipple

90 Degree Elbow Socket Weld

90 Degree Elbow Thread

Cap Socket Weld

Cap Thread

Coupling Socket Weld

Coupling Thread

Half-Thread Short Pipe

Hex. Head Bushing

Hex. Head Plug

Round Head Plug

Square Head Plug

Tee Thread

Union Sw

Union Thread

Forged Steel Pipe Fittings Type Technical Specifications

Difference Between Malleable Iron and Forged Pipe Fittings

Malleable iron fittings are lighter fittings in 150# and 300# pressure class. They are made for light industrial and plumbing use up to 300 psi. Some malleable fittings such as floor flange,

lateral, street tee and bullhead tees are not commonly available in forged pipe fittings.

Malleable iron offers more ductility that is often required in light industrial use. Malleable iron pipe fitting is not good for welding (if you ever need to weld something to it).

Malleable iron fittings, also called black iron fittings, are available up to 6 inch nominal pipe size, though they are more common to 4 inches. Malleable fittings include elbows, tees, couplings

and floor flange etc. Forged Pipe Fittings are available as socket weld pipe fitting or threaded pipe fitting. Threaded pipe fittings and socket weld pipe fittings are available up to 4 inch

nominal pipe size.

Forged Iron Threaded or Socket Weld Fittings are more expensive in sizes bigger than 2 inch compared to their malleable iron or butt weld counter parts.

Malleable Iron Fitting and Forged Pipe Fitting differ in material metallurgy, pressure class and application. It is important to select appropriately between them for the intended application.

Advantages of Forged Steel Pipe Fittings

Strength: Forging pipe usually results in a strong and very reliable end-product because forging causes the grain flows of the steel to alter and align. In other words, the steel becomes more

refined and the pipe’s structure is changed unequivocally resulting in sheer strength and high impact resistance.

Longevity: Forging excludes the potential for porosity, shrinkage, cavities, and cold pour issues.

Cost-effectiveness: It is generally accepted that the process of forging is very economical as no material is wasted during the process of production.

Flexibility: The steel forging process is very flexible and can produce many different pipes of varying sizes.

We also have types of flanged gate valves for sale, if you have needs, please contact us.