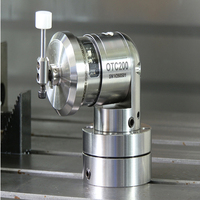

Optical Tool Setter

Product Quick Detail

- FOB Price

- USD $3,600.00 / Piece

- Minimum Order

- 100

- Place Of Origin

- China

- Packaging

- Carton

- Delivery

- 2-10 Days

Specifications

OTC200 optical tool setter/optical tool presetter is a wireless tool setter, optical coded signals are used to transmit information between the CNC tool setter and the receiver. It mainly used in

various specifications of small to medium machining centers, CNC milling machines, drilling machines center, electronic touch off tool and so on. It used for broken tool detection and rapid

measurement of tool length and diameter on a wide range of tools.

Parameter of Optical Tool Setter

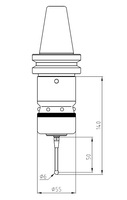

OTC200:

Measuring direction ±X,±Y,+Z

Arbitrary direction swinging angle X-Y±12°, Z +5 mm

Repeatability (2σ) ≤ 2 μm;

Optical signal receiving/sending distance >3m

Model of the standard stylus M0-S31.5-CP12.7

Model of the battery 14250,3.6 (V), 2 Pcs

Seal grade IP68

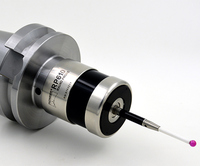

Technical Characteristics of Optical Tool Setter

Tool setter switch on/off method: M code on/off;

Compatible with Pioneer optical modulated receivers (OSI-20M and OSI-30);

Exceptional resistance to light interference with modulated transmission;

Cable-free for unrestricted machine movement and ease of installation.

Application of Optical Tool Setter

For tool measuring on small to medium machining centers.

Detect broken tools in-process

Compensate for environmental and machine conditions

Reduce non-productive time and scrap and increase productivity and profits

Pioneer is a professional probe manufacturer, we provide probe manufacturing, tool pre setter, haas tool setter, haas tool presetter, presetter tool, cnc measuring probe and etc. Want to know more

about haas tool setter calibration? Please contact us.

- Country: China (Mainland)

- Address: 1F, Building 4, Tianping Road 22, Daoli District, Harbin, China. P.C.:150078

- Contact: Una Yang