Automatic Rising Hydraulic Bollard JDBRD-2

Product Quick Detail

- Place Of Origin

- China (Mainland)

- Unit Price

- 800~1800

- Minimum Order

- 1

- Packaging

- 1 peice per carton

- Delivery

- 10 Days

Specifications

1. The obstacle can be lowered by a manual operation directly on the hydraulic pump in case of power failure

2. The bollard finishing is available in painted steel and in brush stainless steel

3. The control unit is housed in a cabinet which could be up to 80m remote

4. Easy underground pit laying and limited excavation

5. Sleek design and pleasing aesthetics

6. High duty cycle, ensuring lasting performace and intensive use

7. Quick and easy to install because the foundation box can be assembled on site

8. Long service life

9. Integrated hydraulic unit

10. Equipped with anti-vandal function, which detects a forced command, to reset the bollard and activate an alarm

Applications

Embassies

Consulates

Military installations

Airports

Railway stations

Bus stations,

Oil & gas refineries

Parameters

| System Control | Electric hydraulic drive |

| Power Supply | AC220V/ AC110V±10%, 50/60hZ (control voltage DC24V) |

| Material | #304 stainess steel ( #201, #304, #316 stainless steel optional) |

| Diameter | φ168mm, φ219mm, φ273mmoptional |

| Thickness | 6mm, 8mm, 10mm, 12mm, 15mm, 20mm optional |

| Box Round Diameter | φ370mm. Height: 990mm |

| Through Pressure | Bearing over 80 ton container truck |

| Outside Bollard Height | 600mm |

| Remote Control Range | ≤ 30 meters |

| System Power | 3.7 KW |

| Rising Time | ≤3~5 seconds (adjustable) |

| Falling Time | ≤ 3 seconds (adjustable) |

| Working Temperature | -35ºC~75ºC |

| Storage Temperature | -10ºC~65ºC, anti-rain, anti-dust, anti-moisture |

Automatic Rising Hydraulic Bollard Design

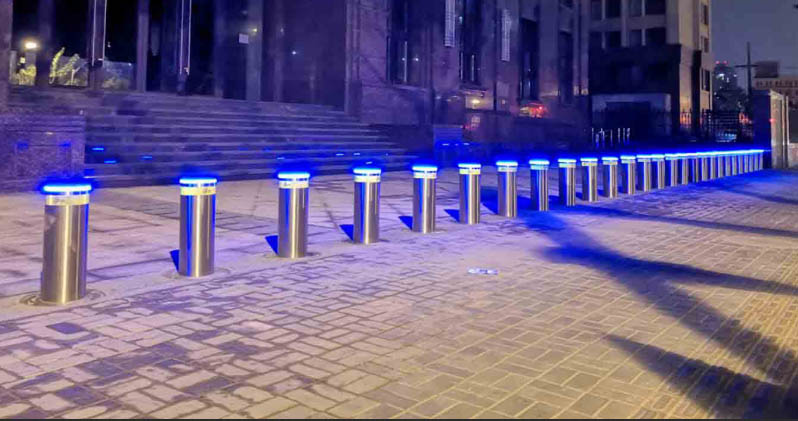

Automatic Rising Hydraulic Bollard Project Case

- Country: China (Mainland)

- Business Type: Exportor & Supplier

- Market:Africa,Asia,Europe,Middle East,Americas

- Founded Year:2019

- Address:Room 801-12, 8th Floor, Block 3, No. 66, DaYu East Road, DeYuan Town (JingRong Town), PiDu District

- Contact:Luke Zhang

Other products from ChengDu Jayda Intellitech Co., Ltd

Relate products of Automatic Rising Hydraulic Bollard JDBRD-2

Functions and Features : 1.Durable,Overload,Operate Smoothly,Low Noise,Fast speed up&down 2.Micro-control technology makes bollards work stable and reliable,Easy integrate to other systems 3.Compatible with road barrier,Turnstiles and other access system control to achieve ...

Place of Origin:United Kingdom Automatic Crash Rated High Impact Road Bollard. Crash testing according to highest European standards PAS 68/69 criteria. ...