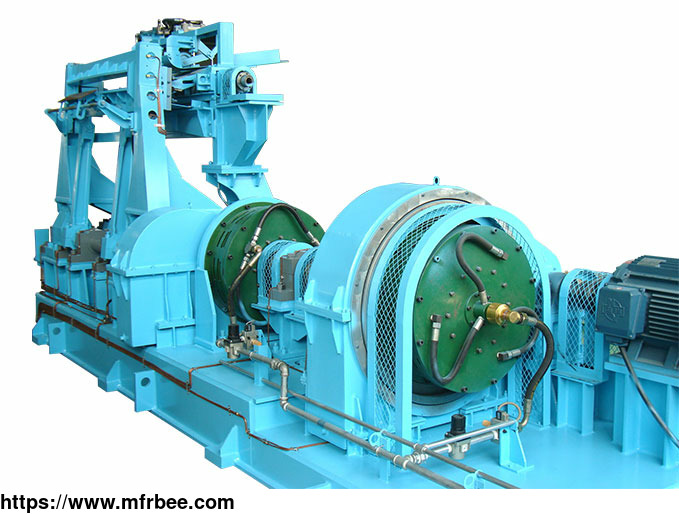

Rotary Shear for Annealing and Galvanizing Line

Specifications

In order to ensure that the tearing surface of the strip is smooth, it is necessary to ensure that the upper and lower knife planes are relatively parallel as much as possible. The rotary shear for

annealing and galvanized lines produced by BOYA have undergone precise processing and strict debugging before leaving the factory to ensure that the assembly accuracy is at a high level.

Application Scope of Rotary Shear for Annealing and Galvanizing Line

Material Strip thickness Strip width Tensile strength Shear rate

High-strength steel and ordinary steel 0.1-3.0mm 500-2300mm ≤1600MPa ≤600m/min

Structure Advantage of rotary metal shear for Annealing and Galvanizing Line

The single-side shearing knife box of the disc shears is for one use and one preparation, and can be quickly switched through the rotary mode, so that the unit can quickly change the tool without

stopping the machine.

The disc cutter is equipped with a tool change and maintenance platform, which can realize online tool change and maintenance of the spare tool box.

The disc knife adopts the end face grinding method, the hydraulic nut is locked, the upper knife adopts the front rigid positioning, and the lower knife adopts the rear rigid positioning, which can

greatly improve the convenience of equipment operation and maintenance and reduce the ineffective consumption of spare parts.

Equipped with cutter cleaning device and scraper mechanism, it can guarantee and prolong the service life of the disc blade.

Electromechanical and hydraulic control integrated products, equipped with reliable Siemens control system and optimized process adjustment template, can effectively ensure stable product quality.

As one of the most professional fine blanking press manufacturers, we provide sheet shearing machine, Steel plant finishing line, rotary shear for sale, mini rotary metal shear, mini rotary shear,

rotary sheet metal shear, throatless rotary shear, sheet metal coil processing and etc. Want to know more, contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Founded Year: 1999

- Address: NO.3 Tianlai Road, Auto Industrial Park, Hi-Tech Zone, Xiangyang, Hubei, China

- Contact: BOYA