Application of Ndt Inspection Equipment

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Jiangsu Province,China

- Packaging

- custom wooden box

- Delivery

- 15-90 working days

Specifications

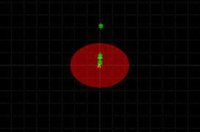

Ndt inspection equipment is widely used in industry, such as nuclear industry, weapon manufacturing, machinery industry, shipbuilding, petrochemical industry, railway and high-speed train,

automobile, boiler and pressure vessel, special equipment, customs inspection, etc.

Many products need Ndt inspection equipment, especially X-ray nondestructive testing equipment. Usually, we can use X-ray for non-destructive testing of automobile parts, non-destructive testing of

precision casting parts, non-destructive testing of alloy parts, non-destructive testing of cylinder head, slices, fan blades, ductile iron, compression parts, etc. X-ray can be used to detect

on-line pore, inclusion, porosity and crack defects in various products. It improves yield and reduces defective products. X-ray nondestructive testing technology can be said to be widely used. The

main characteristics of X-ray Ndt inspection equipment are: high resolution, high definition; small parts testing; highly integrated system, high cost performance; compact equipment, small area;

high detection accuracy, small defects can be found; Higher detection image quality; Safety guarantee of equipment operation; With multi-purpose, it can customize fixture. Humanized software

design, easy to operate; it is customized according to customer needs, providing solutions; all-network after-sales service platform; cloud platform, huge data, tracing the origin.

As one of the most professional ndt equipment manufacturers, BKN provides ndt testing machine, ndt ultrasonic testing equipment, etc. Want to know more? Please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Contact: bkneddy .com