GSET-551 Steel Wire Eddy Current Flaw Detector

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- Jiangsu Province,China

- Packaging

- custom wooden box

- Delivery

- 15-90 working days

Specifications

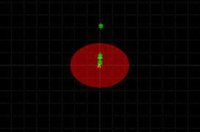

GSET-551 Steel Wire Eddy Current Flaw Detector Brief Introduction

Using the eddy current signal processing method and high-performance DSP algorithm, the NDT wire rope tester detection ability of micro-crack is as high as 0.05mm deep crack.

Using computer digital technology and \"digital eddy current detection technology\" to achieve high-speed data processing capabilities, detection speed can be reached to 1~500m/min. Technology can effectively suppress all kinds of interference signals. It has waveform, amplitude, phase, X-axis and Y-axis signals.

The professional \"digital filtering\" is adopted to effectively suppress the interference signal in the field and ensure the accuracy and stability of the detection.

Features of GSET-551 Steel Wire Eddy Current Flaw Detector

1. LF testing sensitivity

The detector detects the minimum metal cross-sectional area change and the minimum length of the damage length corresponding to the local damage.

2. LMA testing sensitivity

The detector detects the minimum metal cross-sectional area change and the damage length minimum size corresponding to the metal cross-sectional area loss.

3. LMA repeatability error

The maximum value of the random error obtained by performing multiple consecutive measurements of the same metal cross-sectional area change in the same test sample under the same test environment and conditions within the instrument range.

4. LMA linearity error

Within the range of the instrument, the metal cross-sectional area of the test sample is linearly proportional to the absolute value of the maximum deviation between the measured curve of the instrument and the calibration curve fitted by the measured value of the cross-sectional area of the metal.

5. LMA error of indication

The value of the metal cross-sectional area loss measured by the instrument minus the actual value of the metal cross-sectional area loss within the instrument\'s range.

6. LMA linearity error

In the range of the instrument range, under the condition of the length loss of the cross-sectional area of the metal, the cross-sectional area loss of the metal on the wire rope measured by the detector is matched with the value of the loss of the cross-sectional area of a group of wire ropes measured by the instrument. The absolute value of the maximum deviation between the calibration curves.

7. Testing distance resolution

The detector is capable of detecting the resolved minimum distance.

8. Dual function instrument

The detector can detect and display changes in metal cross-sectional area loss (LMA) on one channel, and detect and display local damage (LF) on the other channel. The detector recording device can be a computer, graphic recorder or other matches. device.

9. Single-function instrument

The detector cannot simultaneously detect and display metal cross-sectional area loss changes and local damage, and can only detect and display one of them. The detector recording signal device can be a computer, a graphic recorder or other matching devices.

10. Wire rope electromagnetic tester

The detector principle and composition meet the requirements of the GB/T 21837-2008 standard, and it has a detector for detecting distance display, data storage or recording function.

As one of the most professional mfl suppliers, BKN provides ndt testing machine, wire rope ndt, eddy current testing, etc. Want to know more? Please contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas

- Contact: bkneddy .com