One-stop Injection Molding Service Expert

Specifications

ISO Class 8 Clean Room

Quality Control

Low & High Volume Manufacturing

Competitive Price

Reliability and Stability

For more than 15 years, Packson Mold has become an excellent manufacturer that is enabled to make parts with high tonnage and large size thanks to our one-stop facility. We are keen to meet your

injection molding needs with single and convenient sources. Thanks to our advanced equipment for tooling making and injection molding, Packson is able to handle all kinds of your needs of injection

molding, mold making. Despite injection molding and mold making, we also specialized in making metal machining parts by CNC machines. We are proud to offer primary, comprehensive project

management, leading-edge assembly line, product distribution, and logistics services that help you keep your company to be controlled well. Our mission has always been to assist customers to create

high-quality parts with competitive prices and fast lead time. Learn more about how you and your business can take advantage of our services today.

Explore Packson's Injection Moulding Services

Are you sourcing the custom plastic injection moulding supplier? Does your project need a competitive price solution? Seeking a one-stop injection moulding expert? We Packson can help you to make

these come true.

Advanced in-house facilities including three ISO class 8 injection molding rooms: One is a lsr silicone molding room. Two are plastic injection molding room

More than 40 injection machines from 10 tons to 1000 tons for making sure your various needs of molding

Full experienced project team who is able to help you make the part from design to part delivery

Look For Professional Injection Mold Making

Here at Packson we help you design and make the mold. Transfer your great idea into reality. Then custom moulding the future and molding the life.

Prototype Mold

2K Mold

Multi-cavities Mold

Precision Mold

Overmolding Mold

Silicone Rubber Mold

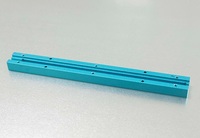

Custom Metal Machining Parts

Based on our cutting, grinding, lapping, and polishing capabilities, our machining centers can provide integrated solutions for machining small-diameter components with strict tolerance by fast

lead time and competitive price.

CNC Metal Machining Parts

Mold Components

Custom Process From Packson

Your expert for a one-stop manufacturer who helps you convert your fabulous ideas into reality from design to finished molded parts and ship parts directly to you. Let's get start this with your

part design drawing.

01

2D & 3D Drawing

JGP, STP,PDF, STEP,DWG, IGS,DXF, IGES.

02

Get RFQ

Normally send quotation within 24 hours.

03

Design & Drawing Assessment

We will analyze your idea first and will send DFM to you first for helping you learn more about your idea and our capabilities.

04

Mold Design & Mold Processing

After confirming the solution of DFM we will start making mold design then start mold processing after we get your confirmation of mold design.

Checking Mold Trial Samples

05

Checking Mold Trial Samples

Reviewing samples and summarizing the issues of sample parts before mass production.

06

Mass Production

Equipped with automatical production line by manipulator's arm also secondary assembly line.

07

Delivery

Providing various options of logistics according to the actual project situation.

See Why Customers Choose Packson

R&D Director-BD

I've worked with Packson for a couple of years now and found it's extremely knowledgeable, helpful, and trustworthy. Packson has been in important partner to our business in the development of a

new product over that time.

I hold Packson in high regard as a professional and dedicated plastic injection molding manufacturer. Packson team's communication skills in English and understanding of the unusual industry-based

English language of injection molding ensure they can converse easily with my team. They also have the ability to quickly understand new ways of doing things and adapting their skills accordingly.

Tooling Procurement Engineer-Aweco

Packson stays for "P"assionate, "A"mbitious, "C"apable, "K"osher, "S"incere, "O"utstanding, "N"ice.

Packson - Your Injection Moulding Manufacturer

Your Expert in Injection Molding

ISO Class 8 Clean Room

Equipped with clean room and certificated with ISO 13485 and ISO 9001, we are able to hanlde your medical OEMS production.

Quality Control

We will check color, appearnce and tolerance by qulity control at every step during manufacturing process.

Low & High Volume Manufacturing

Except long run production, we also can provide better solution for your low-volume production by prototyping tooling.

Competitive Price

Our good investments in euipments and QC system help us to get greater efficiency and higher quality which decrease reject ratio. All these make us send parts to you on time with competitive cost.

Reliability and Stability

Our 24 hours|3 shifts production system help your parts get into market quickly and steadily.

As a reliable injection molding company in china, we can offer kinds of related products for sale, anything you need, please leave us a message.

- Country: China (Mainland)

- Address: No.2 Building,Rongtong Industrial Park,Wulian Village,Fenggang Town,Dongguan,China

- Contact: Packson .com