With the vigorous development of the automotive industry, plastic auto part mold is also developing rapidly. 90% of auto parts are produced by injection molds, which is a huge market opportunity

for auto plastic parts manufacturers .

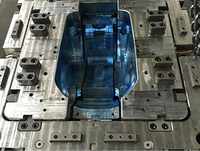

Common large-size auto parts such as car bumpers, fenders, hoods, grilles, doors, rear seats, front covers, and other parts require large-size injection molds. This will require auto plastic mould

parts manufacturers to invest in large machines. For some Automobile parts with complex surfaces, high-speed and high-precision CNC machining is required.

Types of Car Part Mold

Car Seat Mould for Kids

Baby car seat mold affects the plastic car safety seat molding production output a lot. A high efficient cooling system for the plastic car safety seat mold will shorten the shot circle, as a

result, save more machining costs and time. JMT concerns a lot about mold cooling systems and production stability. Our aim is to make customers run molds as little as possible for mold repair

work, the best is free of repair work during mass production.

CUSTOM PLASTIC INJECTION MOLD

Auto Rear View Mirror Housing Mold

Green Vitality Industry supplies automotive rearview shell plastic injection mold since 2013. We can provide you with Innovative solutions, speedy and speedy, and precise design & analysis, high

quality, and longevity on your project.

CUSTOM PLASTIC INJECTION MOLD

Car Light Mould

For cars, lamps are an essential function. The most important part of the lamp is the headlamp body, reflector, decorative frame, and lamp mirror. Green Vitality provides car lamp cover mold design

and manufacturing solutions.

CUSTOM PLASTIC INJECTION MOLD

Automotive Air Grille Mold

The car grille is a mesh part of the front of the car. It is a very important part of auto parts. It has the functions of decoration, protection, and ventilation. Green Vitality is an experienced

on making kinds of automotive parts molds, especially in plastic car air grill mold.

CUSTOM PLASTIC INJECTION MOLD

Auto Bumper Mould

Automobile bumpers are made of plastic materials, which not only have decorative functions but also have devices for absorbing and buffering shocks and protecting the body and the driver. Green

Vitality specializes in bumper making, bumper molding, car bumper manufacturing process.

Process of automotive injection molding

In order to effectively control the development cost of mold building, reduce the cost of later repair molds, accelerate the progress of product development, and fully verify product performance as

much as possible. In the mold development process, auto part verification needs to be carried out in several stages.

PROTOTYPE SAMPLE

Usually made by rapid prototyping parts, CNC processed rapid prototypes, prototype sample is used for dimensions and assembly verification. The dimensional accuracy of the prototype sample is high,

and the production cycle is fast, usually within 1 week.

SOFT TOOLING

After quick sample verification, after changing the problems found, a small displacement trial assembly verification will be carried out as verification before the formal plan. To carry out a more

adequate verification and avoid the risk of mold scrapping, usually at this stage, lower-cost soft tooling is developed first, and the material and structure of the parts are consistent with the

mass-produced parts. The development cycle of steel molds is usually long, with small parts within 1 month, and large parts even require more than 4 months of development time. Soft molds can

usually produce no more than 10,000 shots.

PRODUCTION TOOLING

After the parts have been fully verified and approved, the official steel mold is developed. The official steel mold can produce 50000, 100000, or 300000 parts according to the different steel

materials used, and select the appropriate steel material according to the planned output.

01

PROTOTYPE SAMPLE

02

SOFT TOOLING

03

PRODUCTION TOOLING

Advantages of Green Vitality Industry Auto Part Mold

Flexible customization

Green Vitality can produce various auto parts, OEM service is available.

Automotive Injection Molding Experts

The perfect combination of advanced equipment and professional technology ensures that the auto parts we made exceed your requirements.

Delivery on time within budget

We help customers control costs, create and execute the most efficient schedule for each project, taking full advantage of our supply chain network and mold processing and injection molding

capabilities.

Added Value

Our engineers can share in-depth knowledge and experience in auto parts design, and help customers select the best plastic for performance and budgetary goals.

Auto Part Mold Faqs

FAQ

Q:

What is the best material for injection molding auto parts?

A:

1. Different parts demand different plastic materials.

2. Nylon is mainly used in automotive engines and engine peripheral parts, etc.

3. PBT is widely used in the production of automotive parts such as bumpers, carburetor components, fenders, spoilers, instrument panels, car ignition, gas pedal, clutch pedals, etc.

4. POM is very suitable for manufacturing automotive pumps, carburetor parts, fuel lines, power valves, universal joint bearings, motor gears, cranks, handles, instrument panels, car window

lifters, electric switches, seat belts buckles, etc.

5. PC is mainly used in automotive parts such as exterior and interior trim parts, dashboard surroundings, antifreeze plates, door handles, underflow plates, brackets, steering column sheathing,

decorative plates, air conditioning system parts, lamp parts, and other automotive parts.

Q:

What is the common steel for auto parts molds?

A:

738, 738H, NAK80, S136, etc, the mold steel is dependent on the mold life and product quantity. We can select the steel type according to your request.

Q:

What factors affect the price of auto parts molds?

A:

The size, structure, appearance requirements of auto parts, mold cavities number, and mold life requirements are the main factors that affect the price of auto parts molds.

Q:

What is the lead time for an auto part mold?

A:

Generally, a typical mold takes 5-6 weeks from start to T1, it can take 7-10 weeks for multi-cavity molding or more complex mold. longer lead time factors may be due to the type of injection

systems, such as hot runners, high surface, and high tolerance dimensional requirements.

Q:

Why is it necessary to make a prototyping mold for auto parts?

A:

Because prototyping mold is a very effective method, new products can be developed early to better meet specifications at a lower cost. The samples can also be obtained in the fastest way so that

the functional performance of the parts can be tested before investing costly series of molds.

If you want to know more details of injection molds for sale, please visit our website.