THREE PART SYRINGE PLUNGER MOLD

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 1-3Months

Specifications

The Three Part Syringe Plunger from PLUSLINK is a durable and easy-to-use device designed to help inject medication into the body accurately and safely. It is constructed from three separate parts

made from medical-grade plastic, allowing for easy maintenance, cleaning and assembly. The plunger is compatible with most standard syringes and is easy to operate, making it ideal for use in

clinical settings.

USAGE METHOD OF THREE PART SYRINGE PLUNGER MOLD

Feed the material into the injection loading machine.

Install the mold using a sling.

Debugging and preheating the machine.

Starting producing.

Disassemble the mold and keep it clean.

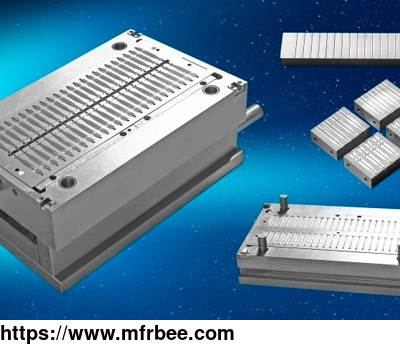

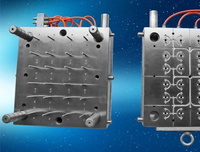

ADVANTAGES OF THREE PART SYRINGE PLUNGER MOLD

Frame of mold is made of 60#quenched and tempered steel.

P20H .2738. 718 are available. It also can be produced according customer's requirement.

The precision locator is added to prevent the dislocation.

Mold inserts materials: Cr12, SK11, DC53, or others required by customers.

To replace easily and prolong service life. The inserts can be separated by individual bar that contains 2-4 cavities. Our design is reasonable, with a sturdy structure and stable performance,

which can greatly improve production efficiency and mold service life.

Application of Three Part Syringe Plunger

The Three Part Syringe Plunger is commonly used for medical applications such as drug delivery, laboratory analysis, and surgical procedures. It consists of a plunger rod, a stopper, and a body. It

is designed to provide accurate, safe and efficient delivery of fluids, medication, and other substances.

There are many medical molding companies, but we are one of the best choices for you.

- Country: Singapore

- Business Type: Manufacturer

- Address: 10 ANSON ROAD #11-07 INTERNATIONAL PLAZA SINGAPORE

- Contact: LINKPLUS com