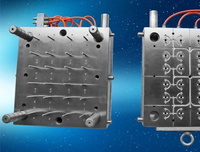

SYRINGE GASKET MOLD

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 1-3Months

Specifications

It can be used for all kinds of dimension of pistons. There are materials of 4Cr13 or P20H, 2738, 718 stainless steel and etc. It can be selected for mold frame, material customer nominated is

acceptable. It is the high precision of mold inner insert is S136, 2316 mirror stainless steel or others required by customers. Our mold has sound structure, and stable behavior, which is good for

promoting productive efficiency.

USAGE METHOD OF SYRINGE GASKET MOLD

Prepare the mold, ensure the mold is clean and dry.

Prepare the injection molding machine: Select the appropriate injection molding machine and set it up according to the manufacturer's instructions. Preheat the machine and mold to the recommended

temperature.

Load the material: Load the appropriate plastic material, such as Silicone, into the injection molding machine hopper. Ensure that the material is clean, dry, and free of contaminants.

Inject the material: Activate the injection molding machine, and the plastic material will be molten and injected into the mold cavity to fill the space of the gasket.

Allow the plastic to cool: After injection, allow the plastic to cool and solidify within the mold.

Eject the finished product: Once the plastic has cooled completely, eject the finished products by using an ejector system or opening the mold plate.

ADVANTAGES OF SYRINGE GASKET MOLD

Consistency: The use of a mold ensures a consistent size, shape, and quality of the gasket produced every time.

Time-saving: Injection molding is a fast and efficient process that produces multiple gaskets simultaneously, reducing production time per piece.

Cost-effective: Injection molding allows for the mass production of gaskets at a lower cost per piece than other production methods.

Customization: Mold design allows for customization of the size, shape, and other features of the gasket to meet specific requirements.

High precision: Injection molding machines can produce gaskets with high precision at a tight tolerance.

Reduced material waste: Injection molding produces minimal scrap compared to other production methods, reducing material waste.

If you are looking for a reliable medical molding factory, don't hesitate to contact us!

- Country: Singapore

- Business Type: Manufacturer

- Address: 10 ANSON ROAD #11-07 INTERNATIONAL PLAZA SINGAPORE

- Contact: LINKPLUS com