Insert Mold

Product Quick Detail

- FOB Price

- USD $3,000.00 / Piece

- Minimum Order

- 25

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

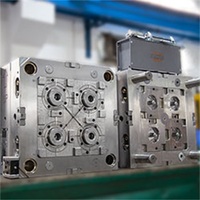

Insert Mold

USM molds focus on structural parts injection molds, gas-assisted water-assisted injection molds, small parts plastic molds, precision plastic molds, and plastic parts product molds, from mold

design to mold manufacturing, mold assembly test molds, product injection molding processing, and the entire process. Service, the precision of the mold is 0.005mm, and the precision of the

injection product is 0.02mm. If you have any ideas about molds and products, please do not hesitate to contact us directly.

INSERT MOLD TYPES

Insert Mold Parts

Insert injection molding is injected with plastic part processing, the insert can be plastic or metal, normally it will be metal parts or thread parts, they must be in a fixed area before

injection, so it will be fitting very well after injection finishing. Normally these products request a high standard of strength.

Plastic Insert Mold

The easy formability and bendability of resin complement each other with the rigidity, strength, and heat resistance of the metal, and they can be made into complex and exquisite metal-plastic

integrated products.

Metal Insert Mold

For rigid molded parts and curved elastic molded products on rubber gaskets, after injection molding on the substrate, an integrated product can be made, and the complicated operation of arranging

the sealing ring can be omitted, making the automatic combination of the subsequent processes easier. Because it is the joining of the molten material and the metal insert, compared with the

press-in molding method, the gap of the metal insert can be designed to be narrower, and the reliability of composite product molding is higher.

Common Manufacturing Methods of Injection-molded Insert Products

Generally, there are two methods for making insert moulding products:

1. Place the insert into the mold before injection molding, and then inject together, due to most of the inserts are manually placed into the mold, this method will reduce the production efficiency

of injection molded products, according to the current production technology conditions, it is gradually moving towards automatic production.

2. Putting the insert into the plastic part after finishing the injection by the welding process, common press-in methods include an ultrasonic press-in method and heating press-in method. In order

to make the positioning accurate, a tapered hole is often reserved at the embedded part, the advantage of this method is higher production efficiency, but requires more types of equipment, more

processes, and may cause flash around the insert.

Design Considerations for Insert Mold

1. The molding of metal inserts is prone to uneven molding shrinkage, so the limit test of the shape and dimensional accuracy of important parts should be done in advance.

2. During the injection process, the metal insert is easy to deform and mismatch, so full consideration should be given to the mold composition and the design of the mold shape that is easy to

maintain the metal insert, for products whose insert shape cannot be changed which will need to make some testing in advance.

3. When the arrangement of the metal inserts is separated and the conveyor is used, the contact between the metal inserts and the inserts and the vibrating ball will cause slight damage to the

insert surface and affect the quality of the product, the quality should be confirmed limit range in advance.

4. The jaggedness, warpage, material thickness difference, diameter difference, and thickness difference caused by gold-plating processing of metal inserts should be measured in advance, on this

basis, the matching selection design of the automation device and the design of the mold structure are carried out.

5. Predictable items that restrict the mold structure, such as the position of the mold gate, the molding cycle, etc., should be resolved in advance or corresponding improvement measures.

6. It should be confirmed whether the metal inserts need to be preheated or dried, the purpose is to ensure product quality and stability of molding.

7. The various detection devices installed in the mold are used to ensure the stability of the molding action when the mold is affected by environmental conditions such as heat, force, and

vibration, it should be confirmed whether it is used.

8. The part of the insert placed in the mold should be designed to be cylindrical in order to make and fixing of metal inserts, so that it is convenient to place the insert in the relevant

positioning hole on the mold, such as the placement of the insert the angle is required, and a positioning structure is also required to ensure that the insert can be quickly and reliably

positioned when placed in the mold.

As one of insert molding manufacturers, we will do our best to meet all the needs of customers.

If you are looking for a reliable china mold maker, please contact us, and we will be your best partner.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2017

- Address: No.136 Xingwu Road,Wusha Community, Changan Town,Dongguan, China

- Contact: usm mold