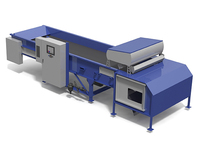

AIR SEPARATOR

Product Quick Detail

- FOB Price

- USD $100,000.00 / Piece

- Minimum Order

- 5

- Place Of Origin

- DeZhou City, Shandong Province

- Packaging

- N/A

- Delivery

- 60-120 Days

Specifications

The waste stream is blown by wind and air in the air separator system, which subsequently employs gravity to separate the trash. As a trash sorting machine, A conveyor transports a waste stream to

the pneumatic separators, where heavy wastes with solid shapes (such as glass bottles and plastics) are delivered directly to the air separator's bottom. Plastic and glass bottles are the first to

fall, then light wastes like film and paper are blown away by the air and hydronic dirt separator from the air flow and land on the end conveyor for separation. The air flows through the wind

separator as the cyclone collects the dust.

Air separator advantages and disadvantages

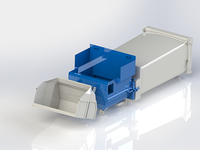

This air separator units, which is primarily made up of a material conveying system and a blower system, has a simple structure, a good operating effect, and is simple to maintain.

To achieve the desired wind sorting effect, the feeding conveyor angle and air nozzle angle can be adjusted, and the feeding angle and nozzle angle can be flexibly modified according to the

material composition.

The separation chamber's inlet and outlet, as well as the distance between the drum and the discharge channel, are all adjustable, allowing for flexible air separation distance adjustment between

the separator and the rotating drum.

The light and heavy materials are separated and sorted aerodynamically, with the heavier component being transferred to a storage bin or discharge belt before passing through the drum through the

dumping channel. The lighter material is blown through the separating drum, sucked into the settling chamber, and released.

Application Of Air Separator

Material recovery system (MRF)

Mechanical biological treatment (MBT)

Plastic recycling center

Landfill waste sorting plant

Operating Principle Of Air Separator

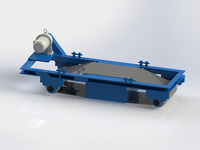

The feeding conveyor, rotating drum, blower, heavy material conveyor belt, settling chamber, and light material conveyor belt are the primary structural components of the Hengchuang wind shifter.

According to the principle of aerodynamics, controlled airflow as a sorting medium, under the action of controlled airflow to make the selected material according to the density and size of the

wind selection method, airflow can be lighter materials (such as paper, feathers, plastic bags, dead leaves, etc.) up to take away or horizontal direction to a farther place, while heavy materials

due to rising airflow can not support them to land, or due to ineligibility. As a result, the wind sorting process is based on the law of solid waste settling in the air to fulfill the goal of

sorting and recycling.

Q&A Of Air Separator

How the Wind Shifter Works?

The wind shifter blows light materials (film, paper, fabric, etc.) into the settling chamber, where they are delivered to the next link via the conveyor, and the heavy materials fall directly into

the conveyor below.

When the Wind Shifter is in Operation, How Much Dust is Produced?

Because the wind shifter is an airtight device with little dust leakage, you can add a dust collector to collect dust for centralized processing.

For more information about air separator construction, please feel free to contact us!

If you need any kinds of waste management machine, please contact us, as on e of the most professional waste management equipment suppliers, Hengchuang is willing to offer you high quality

products.

- Country: China (Mainland)

- Founded Year: 253000

- Address: Room 801, office building, No. 1697, Dongfanghong West Road, Xinhu sub district office, Decheng District, DeZhou City, Shandong Province

- Contact: hcmswrecycling com