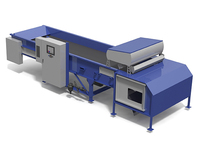

CONVEYOR IDLER

Product Quick Detail

- FOB Price

- USD $100,000.00 / Piece

- Minimum Order

- 5

- Place Of Origin

- DeZhou City, Shandong Province

- Packaging

- N/A

- Delivery

- 60-120 Days

Specifications

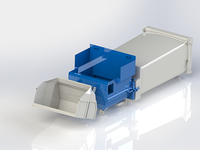

Hengchuang, one of the top trough rollers suppliers in China, produces different types of conveyor idlers including various grooved rollers, buffer rollers, parallel rollers, etc. The idler roller

conveyor specifications range from 89 to 219, according to different belt conveyor idler types for selection and installation. Including iron rollers, rubber rollers, etc. The return training idler

rollers are one of the most commonly used and easy-to-maintain parts of the belt conveyor.

Hengchuang Belt Conveyor Idler Types

Types A B C D E F G H I

89×190 89 190 20 220 200 47 14 10 2.5 204

89×240 89 240 20 270 250 47 14 10 2.5 204

89×305 89 305 20 335 315 47 14 10 2.5 204

89×600 89 600 20 640 610 47 14 15 2.5 204

89×750 89 750 20 790 760 47 14 15 2.5 204

89×950 89 950 20 990 960 47 14 15 2.5 204

108×375 108 375 25 408 385 62 18 11.5 3.5 305

108×455 108 455 25 488 465 62 18 11.5 3.5 305

108×525 108 525 25 558 535 62 18 11.5 3.5 305

108×1150 108 1150 25 1200 1160 62 18 20 3.5 305

108×1400 108 1400 25 1450 1410 62 18 20 3.5 305

108×1600 108 1600 25 1650 1610 62 18 20 3.5 305

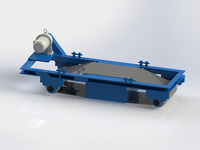

Features of troughing rollers for sale

Shaft, the roughness is 0.8 microns, and the diameter is 0.01 mm bigger than the bearing inner diameter, to ensure the axial displacement and axial load.

The tube is an ordinary pipe, a thickness from 2.5mm to 4mm, and an ovality between 0.7 mm to 1 mm. produced roller runout between 0.7 to 1mm.

The bearing is made of by Chinese ordinary double non-contracted seal, the bearing inner race have no V-groove, grease is great wall lithium grease, the temperature range of minus 10 degrees to 120

degrees above zero, bearing is dustproof but not waterproof, the gap is C3, the noise of 43-45 db.

The seal is 7 items, including 4 pieces nylon 6 and 3 pieces steel seal note, 2/3 of the great wall lithium grease, could dustproof and waterproof.

The snap is 2mm thick, and 65M of spring steel material.

We use machines to polish to make sure the surface is smooth, and make a good painting. the paint is common to paint, has different colors.

The roller is bare packing for itself. you can choose an iron plate, wooden box and so on.

Function of Idlers in Belt Conveyor

In general, conveyor rollers and idlers serve to help move the belt or provide a specific amount of resistance in the belt and pulley structure. hdpe conveyor idlers pulleys can also help with gear

ratios and other engineering aspects of the conveyor belt system. In some cases, conveyor roller models may have a belt tensioner feature, where moving the rollers can change the tension of the

belt. These are usually detailed, as some of them may be difficult to use because of necessary tooling or unusual specifications.

Many specific conveyor idler design consist of more than one roller, with sections of the idler attached to the belt at different locations to keep the belt properly routed and running well. These

designs may also include a metal frame for stabilization. Some designs have handles that can be used to adjust the idler pulleys to help the conveyor move correctly. All of this leads to structural

versatility in fitting these elements into existing industrial trash conveyor systems

For more information about trash handling equipment, please feel free to contact us!

- Country: China (Mainland)

- Founded Year: 253000

- Address: Room 801, office building, No. 1697, Dongfanghong West Road, Xinhu sub district office, Decheng District, DeZhou City, Shandong Province

- Contact: hcmswrecycling com