Key Seat Wiper

Product Quick Detail

- Place Of Origin

- Jinan City, Shandong Province. P.R. China

- Minimum Order

- 1

- Packaging

- wooden box or loose

- Delivery

- 45days

Specifications

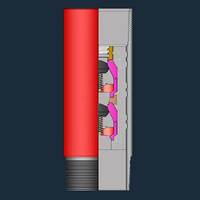

Sliding sleeve type key seat reamer consists upper sub, mandrel, lower sub, sliding sleeve and so on, as shown in diagram. The sliding sleeve could move upward or downward and rotate freely on the

mandrel, there are several spiral hard alloy blades welded on the sliding sleeve, and several saw-tooth jaws on both the top and the bottom of the sleeve. When the saw-tooth jaws on the bottom end

of upper sub are fitting with the saw-tooth jaws on the top end of the sliding sleeve, pressure and right hand rotary of the drill string cause jarring and freeing the sticking sliding sleeve; The

saw-tooth jaws on the bottom end of the sliding sleeve are fitting with the saw-tooth jaws on the top end of the lower sub that could exert a certain tension force on the keyseat department to back

reaming to destroy keyseat.

Features:

The keyway expander is a downhole special tool designed to break the wellbore keyway. The tool is connected to the top of the drill collar and can effectively enlarge the size of the keyway. It is

a commonly used tool in the drilling process.

The keyway expander is composed of four parts: upper joint, sliding sleeve, mandrel and lower joint.

During normal drilling, due to the weight of the sliding sleeve, the upper and lower joints are engaged with the jaws of the sliding sleeve, and the tool rotates together with the drill string to

reach the keyway position, the sliding sleeve is snapped into the keyway, and the downward pressure can be generated when the pressure is forwarded. The shock action releases the slip sleeve and

forces the sleeve to move downward. On the contrary, if a certain pulling force is applied to the drilling tool and the forward rotation is made, the lower joint of the keyway expander is engaged

with the sliding sleeve, and the five spirals of the outer circumference of the sliding sleeve are hard and the keyway is cut, thereby breaking the keyway.

Technical Specification:

Specifications - Key Seat Wiper

Model Product Code OD. of. sub(mm) O.D. of blade(mm) LD(mm) Sliding sleeve stroke L (mm) Connection Max .work temperature (℃)

JKQ121 JK12100 115 121 38 317 NC31 <200

JKQ178 JK17800 165 178 70 325 NC50 <200

JKQ203 JK20300 188 203 70 325 NC50 <200

JKQ207 JK20700 188 207 70 325 NC50 <200

SAIGAO GROUP, as an excellent oil equipment suppliers, offers a wide range of oilfield cementing tools for you to choose from.

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2008

- Address:Zhongrun Century Center, No 12111,Jingshi Road, Lixia District, Jinan City, Shandong Province. P.R. China

- Contact:Rex Liu