Composite Metal Guardrails

Specifications

Metallic Beam Guard Rails

We supply metallic beam guardrails, c steel posts and spacers for integrated guardrail solutions for road safety and fencing purpose. Metallic materials are hot dipped galvanized beams, powder coated / painted steel beams, non galvanized black beams.

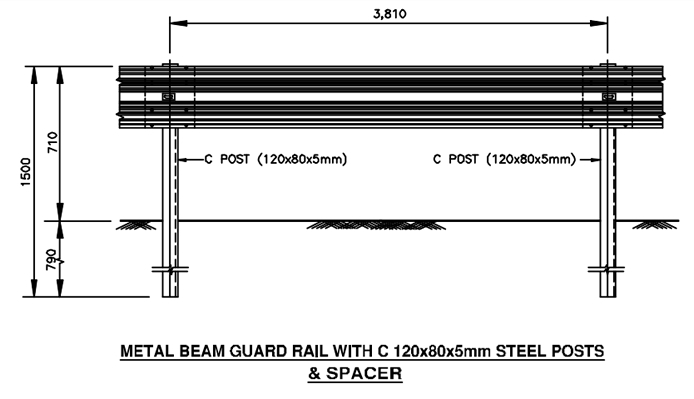

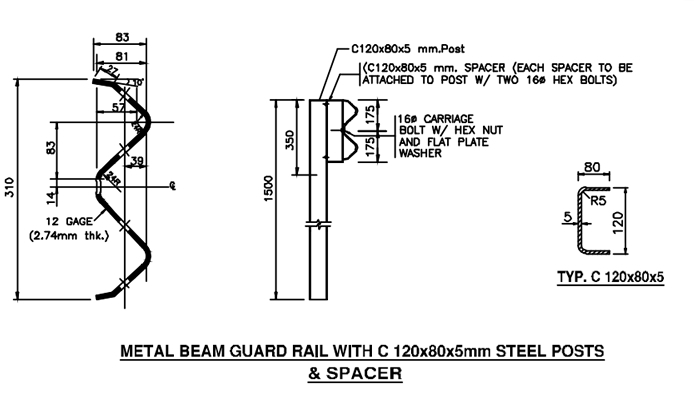

Metal Beam Guard Rail with C Steel Posts and Spacers

Beam Type: 'W' Guard Rail

Post Type: C Post (120x80x5mm)

Metal beam guard rail with c 120x80x5mm steel posts & spacer

W Beam: 12 Gauge, 2.74mm thickness

Spacer to be attached to post with two hex bolts

Composite Guard Rails

Composite Guardrail Barrier composed with metal beams, sound barriers

Metallic Beam for Composite Guardrail System

Metal beams hot dip galvanized steel finish.

Metal Beam Guard Rail

All guard rails complete with posts, breakaway cable terminal sections, foundations, end sections etc.

Corrugated steel beam guard rail and fittings to use on the Project.

MATERIALS

a. Concrete posts and offset blocks shall be precast in the shape and dimensions specified. Cement Type shall be used in the construction of all posts and offset blocks and concrete shall conform to the requirements of Class K300 as specified in Section V (Concrete Works) of these Specifications.

b. Steel reinforcing bars shall conform to the requirements of Section V (Concrete Works) of these Specifications.

c. Steel posts shall be either W200 x 15 or W150 x 14 per design requirement and shall be galvanised as specified. Sections shall conform to AASHTO M160M.

d. Steel rail sections shall conform to AASHTO M180 with the exception that bolt hole spacings shall be 2000 mm center to center or as otherwise shown on the Drawings. They shall be form rolled to the shapes indicated on the Drawings, and shall be hot-dipped galvanized in accordance with AASHTO M111.M

e. All fastenings shall be either wrought iron or medium steel and shall be galvanised in accordance with ASTM A153M.

f. Paint shall conform to the requirements of Section 1202.10 of these Specifications.

g. Timber posts and offset blocks shall be structural timber conforming to the requirements of AASHTO M168 and be treated in conformance with the requirements of AASHTO M133.

CONSTRUCTION

a. Guard rail of the kind and type shall be constructed at the locations as determined by the Engineer.

b. All posts shall be set vertically in the positions. Post holes for steel posts shall be back-filled with a minimum 100 mm surround of Class E concrete tamped into place.

c. Steel rail sections shall be cut, punched and / or drilled in the shop prior to galvanising. Special detail holes may be cut in the field only when necessary and if approved by the Engineer.

d. All nicks, gouges and scratches in the galvanised surface of the railing shall be painted with a high zinc content paint to the approval of the Engineer.

ELEMENTS AND PARTS FOR METAL BEAM GUARD RAIL

a. Breakaway cable terminal sections, both single and double sided.

b. Breakaway cable anchor assemblies at the trailing end of guard rail installations.

c. The remaining metal beam guard rails along the line and grade of the guardrail.

Materials and tools, for the construction and installation of the guard rail including posts, anchors, end sections, reinforced concrete foundations, fittings and fasteners, galvanising and painting, and for all incidental accessories to complete the installations.

RAILING

Railings complete with rails, posts, holding-down bolts and rail joints.

Materials for steel railings shall comply with the appropriate requirements of Clause 1201 of these Specifications.

Materials for Aluminum Railing

a. Cast aluminium railing posts shall conform to the requirements of AASHTO M193M and ASTM B108, alloy S7A – T4 (A444 – T4).

b. Aluminium alloy extruded rail shall conform to the requirements of ASTM B221 alloy, 6061-T6 or 6351-T5 with a minimum yield strength of 2466 kg/cm2 , a minimum tensile strength of 2677 kg/cm2 and as elongation of 10% in 50 mm.

c. Stainless steel hardware for aluminium railings shall be machine bolts or cap screws conforming to ASTM A193M, grade B8, Class 2. Material for stainless steel flat washers and lock washers shall conform to the requirements of ASTM A240, Type 302.

d. Bearing pads shall conform to the requirements of Section XIII (Bearings and Expansion and Fixed Joints) of these Specifications.

RAILING CONSTRUCTION

Railings shall be constructed to the line and grade and shall not reflect any unevenness in the founding construction. All railing posts shall be vertical. For bridges railing shall not be placed on a space until centering or falsework has been removed, rendering the space self-supporting.

Construction of Steel Railings

The fabrication and erection of steel railings shall be in accordance with the appropriate requirements of Clause 1202 of these Specifications.

Construction of Aluminum Railing

The fabrication and erection of aluminium railings shall conform to the requirements of Clauses 1202.01 to 1202.08 inclusive and Clause 1202.11 of these Specifications subject to the following amendments and additions:

a. Cutting – Material 12.7 mm thick or less may be cut by shearing, sawing or milling. Material over 12.7 mm thick shall be sawed or milled.

Cut edges shall be true and smooth and free from burrs or ragged breaks. Reentrant cuts shall be filleted by drilling prior to cutting.

Flame cutting will not be permitted.

b. Bending – Material may be heated to a temperature not exceeding 240oC for a period not exceeding 30 minutes to facilitate bending, unless cold bending is required to retain the original mechanical properties of the material furnished.

c. Rivet and Bolt Holes – Rivet and bolt holes shall be drilled to finished size or subpunched smaller than the nominal diameter of the fastener and reamed to size. The amount by which the diameter of a subpunched hole is smaller than that of the finished hole shall be at least one-quarter the thickness of the piece. The finished diameter of holes shall be not more than 7% greater than the nominal diameter of the fastener except:

i. Slotted bolt holes to take care of expansion shall be provided as called for on the Drawings.

ii. Anchor bolts holes may be up to 25% greater than the nominal bolt diameter with a maximum of 12.7 mm greater than the nominal bolt diameter.

d. Contact with other Materials – Where aluminium alloys come in contact with other metals, except stainless steel, the contacting surfaces shall be thoroughly 12-38 coated with an aluminium-impregnated caulking compound, or a synthetic rubber gasket may be placed between the two surfaces. Aluminium alloys shall not be placed between the two surfaces. Aluminium alloys shall not be placed in contact with copper, copper base alloys, lead or nickel.

- Country: China (Mainland)

- Business Type: Huaway Guardrail Engineering Co.

- Market: 非洲,Americas,Asia,Emerging Markets

- Founded Year: 2004

- Address: No. 09 Neo-Tech District, Development Zone, Dezhou, Shandong

- Contact: zhou feng