Wire Cable Guardrail

Specifications

Wire Cable Guardrails Hot Dipped Galvanized AASHTO M 111-74 Standard for Highway Safety Crasher

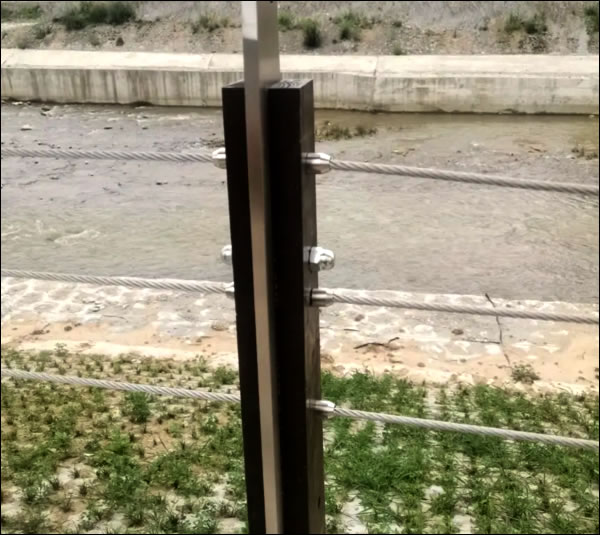

High Tension Cable Guardrail is an economic longitudinal wire cable safety barrier installed along the road for protection and direction of vehicles. Cable guard rail barriers are popularly made of three wire ropes

Wire cable guard rails offer the following advantages over metallic beam guardrails

Tension Cable Guard Rail Barrier Systems

We supply three and four cable railings for standard safety barrier applications.

Five and six layer wire cables are used for reinforced guard railing barriers.

Tentioned Cable Guardrail for Motorway

Structure: 3 galvanized wire ropes, prestressed after manufacture, having a diameter of 1.90 cm, with a nominal breaking load of 17.4 tons. The wire ropes are held in posts approximately 1.8 m apart at 0.85 m above road level, jointed by fitted ends assembled into rigging screw bodies. Each rope "bay" of approximately 600 m is anchored at each end at ground level in concrete anchorages.

4 Cable Guarrails, Hot Dip Galvanized, 450 gm Zinc Coating

Cable Guardrail of 4 Tension Cable

Tension Cable Guardrail as per the followings specification:

Solid cable diameter 19 mm.

Cable: Four pieces

Breaking load: min 17.7 ton

Modulus of elasticity 8,300 kg/mm2

Cables comply with BS 2763 grade 1370 A or to AASHTO M 30

Cables hot dip galvanized, zinc coating 450 gm/m2

All spiral ends, bolts, nuts are to be hot dip galvanized according to BS 729 or AASHTO M 232

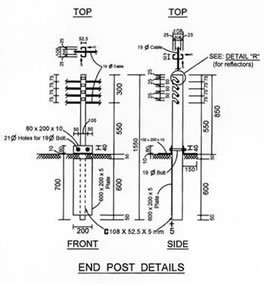

Posts details:

Posts length 1,080 mm, 6 mm thick, solid steel, according to BS 4360, size 100x32 mm for Z post on middle island of the road & type S on the shoulder of the road.

The round edge of the post to face traffic & to be cleaved from one of its edges to the center at 113 mm depth & 22 mm width before galvanization.

Black Polyethylene cover to be placed over each post with a reflector type 1 according to BS 873:part 6. Polyethylene sheet to be placed under the post to prevent sand from penetration to the base of the post.

Cable Guardrail of Wire Rope 3x7 mm - Wire Rope Safety Fence

Wire rope safety barrier and terminal system, components:

Rope wire

Anchor

Wire fitting

Posts: C post with stiffening plate, frame and accessories

Rope Specification:

-Tension on each cable: 14.0 kN.

-Rope: 19 Ø mm, Rope complying to BS 302 Part A

Wire complying w/ BS2763, Grade: 1370.

-Component wire diameter: 3*7 mm.

-Rope E - Module - kN mm2: 81.5

-True breaking load - Ton: 17.7

-Zinc coated - g/m2: 244

-Height over ground for upper wire(4 ropes): 775mm

-Height over ground for lower wire: 550mm

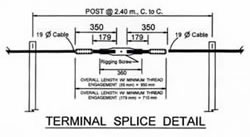

- Distance between any two Rigging Screw on rope shall be 154.0 m.

-Allowable deflection for Post spacing 1.2 m c. to c. is 1.4m and for Post 2.4 m c. to c. is 1.7m

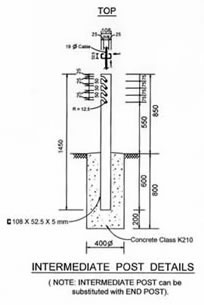

Post Specification:

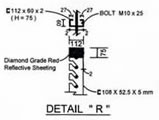

-C108 * 52.5 * 5 mm

- Standard ASTM A446 Grade "B".

- End post length =1550 mm.

- Intermediate post length =1450mm.

-All top post H =75 mm shall be reflectorized w/ Diamond Grade Red Refletive Sheeting.

Terminal splice detail:

Component rope length:

Wire Cable Assembly Instructions

General Requirements for Installation

The erection of wire cable / rope barrier shall be carried out strictly in accordance with the specifications and as shown on the drawings or as directed by the Engineer. The length of each bay will be affected by the central reservation cross-over and the curved points of the road where more anchorages would be required.

Wire cables are fixed to the terminal ends by two popular ways:

Special engineered terminal bracket for holding three or four wire ropes / cables, and the bracket fixed to the ground firmly by anchors;

The second way is to fasten the wire rope directly to the barrier post fixed with fittings.

Wire Ropes Fixing

The ropes are attached to the ground end anchorages by means of a socket. This socket is attached to the anchorage spigot and held in place by a small pin, so that should a vehicle hit this end assembly, the socket can come adrift from the main anchorage. Also attached to this socket and to another point on an anchorage, is a check wire to ensure that the socket does not fly into a vehicle.

The Posts Placing

The posts are placed in appropriate openings in concrete footings and are designed of such material that will allow easy bending movement when the vehicle enters the barrier.

The anchorages and intermediate post bases shall be cast in accordance with the manufacturers' specifications and drawings or as directed by the Engineer.

Changing of following items in assembly will result in varied cable barriers with different strength:

Three Cables, Four Cables and Other Numbers

Generally speaking, more wire cables are used, the higher ability to redirect the errant vehicles used as road guard rails.

Spacing of wire cables and posts

The barrier post often installed with spacing from 6.3 to 32.6 ft. The longer spacing normally means the higher deflection distance.

Wire Cable Tensioning

1, The wire ropes or cables are fixed on the post and tightened to specific tension in accordance with the local temperature and environment.

2, At regular predetermined intervals, a tension indicator device is incorporated to ensure a constant predetermined tension.

3, After tensioning, the ability to preventing vehicles from skidding off the road can be enhanced.

4, Normally the tensions values range approximately from 2,000 to 9,000 lb.

- Country: China (Mainland)

- Business Type: Huaway Guardrail Engineering Co.

- Market: 非洲,Americas,Asia,Emerging Markets

- Founded Year: 2004

- Address: No. 09 Neo-Tech District, Development Zone, Dezhou, Shandong

- Contact: zhou feng