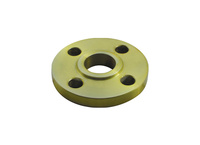

Grooved Butterfly Valve

Specifications

Grooved valves are fixed to the pipes by means of standard clamping couplings. The grooved end clamping system is widely used for indoor fire protection installations since it is a fast and

efficient way of joining pipes due to its high degree of flexibility. Furthermore, it absorbs vibrations and noise transmission through the system.

Grooved Butterfly Valve VS Wafer Butterfly Valve

1. Body Material (Difference):

Grooved end butterfly valve: Ductile Cast Iron

Wafer butterfly valve: Grey Cast Iron; Ductile Cast Iron, Stainless Steel 304/316; Carbon Steel.

2. Pressure (Similarity):

CLASS 125/150; PN10/16/25; 5K/10K/16K.

3. Range of Applications (Similarity):

Both of them are designed for water and air applications

4. Installation (Difference):

Wafer butterfly valves are slightly more economical, but grooved butterfly valves and couplings install quickly and offer several other benefits.

Grooved Butterfly Valve FAQ

What is a Butterfly Valve Used For?

A butterfly valve regulates flow by starting, slowing, or stopping media. The disk opens and closes with a low-torque rotation of 90 degrees and works for any compatible application. Because they

cost less and are lighter weight, the butterfly valve is often preferred over other types of valves.

What are the Benefits of a Butterfly Valve?

In comparison to other valve types, butterfly valves are relatively lightweight, especially at larger sizes. Because they embody a simple and economical design, they have fewer parts, which makes

them easier to repair and maintain. Furthermore, their straightforward design reduces the time required to install one, decreasing labor costs.

For more information about hydraulic valve, please feel free to contact us!

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading