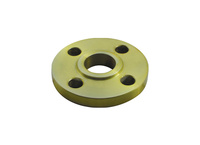

JMW-A1 WCB Metal Seated Flanged Globe Valves

Specifications

Rising stem globe valve steel scaffolding, bolted bonnet structure (OS & Y, BB type), Rotating lifting valve stem and handwheel is an internationally general used globe valve structure.

WCB Metal Seated Flanged Globe Valves VS Stainless Steel Globe Valves

1. Standard:

Both WCB Metal Seated Flanged Globe Valves and Stainless steel globe valves manufacture standard is ASME B16.34,DIN 3356,BS1873,BS5160,JIS B2071

2. Pressure (Similarity):

Both WCB Metal Seated Flanged Globe Valves and Stainless steel globe valves pressure can be Class 150/300/600/900, PN10/16/25/40/63,5K/10K/16K

3. Range of Applications (Similarity):

Stardard: DIN 3202 PN10/16, ANSI CLASS 125/150

Face to face: DIN 3202 F1, MSS-SP-85

Connection flange type: Flange end

4. Installation (Difference):

WCB Metal Seated Flanged Globe Valves have better wear resistance than stainless steel globe valves.

JMW-A1 WCB Metal Seated Flanged Globe Valves FAQs

1. What is Sealing Material of Your WCB Globe Valve?

The sealing material can be WCB, 13CR, SS201, SS304, SS316, STL, or monel.

2. How do Globe Valves Work?

A globe valve manages water flow in a pipeline. It consists of a movable disc-type element and a stationary ring seat. The closing principle of the globe valve is to rely on the pressure of the

valve stem to make the sealing surface of the disc and the sealing surface of the valve seat closely fit to prevent the medium from flowing.

For more information about valves and stainless steel buttweld fittings, please feel free to contact us!

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading