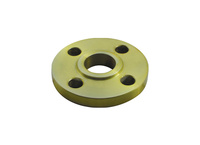

Lever Operated Butterfly Valve

Specifications

Lever operated butterfly valve, has a relatively simple structure, small size, lightweight, and better flow control characteristics. When turning the lever, in the butterfly valve body cylindrical

inner channel, valve disc is associated with the lever around the axis of rotation, rotation Angle is 0° to 90° when rotating to 90°, butterfly valve is in the fully open state. Usually, the lever

operators are available for size DI50-300(2" - 12"), but it is recommended that gear operators be used on size DN200(8") and larger.

Lever Operated Butterfly Valve VS Gear Operated

1. Material (Similarity):

1. Material(similarity):

Body: Grey Cast Iron; Ductile Cast Iron, Stainless Steel 304/316; Carbon Steel.

Disc: Ductile Cast Iron(Nickel-plated or Nylon coated); Stainless Steel 304/316; Aluminum Bronze.

Stem: Stainless Steel 410/416/304/316.

Seat: EPDM; BUNA-N; PTFE; Viton; Hypalon; Neoprene; Metal Seated.

2. Pressure (Similarity):

CLASS 125/150; PN10/16/25; 5K/10K/16K.

3. Range of Applications (Similarity):

API 609; BS5155; MSS SP-67/68; EN593

4. Installation (Similarity and Difference):

A manual butterfly valve in the preparation work before installation, need to confirm whether the lever-operated butterfly valve is suitable for the medium working condition in the pipeline, the

need to allow the handle lever to rotate 90 degrees of operating space, in the pipeline is best installed, can not be installed upside down, regular inspection after installation.

Lever Operated Butterfly Valve FAQ

1. Can Butterfly Valves Be Used for Terminals?

Only Lug-type butterfly valves can be used for terminations and require a special flange connection.

2. What Are the Handle Lever Materials of Butterfly Valve?

Carbon steel; Malleable iron; Aluminum; Stainless steel.

For more information about butterfly valve lever type, please feel free to contact us!

- Country: China (Mainland)

- Address: 911,TOWER B, NEW COOPERATION PLAZA, NO.68 HEZUO ROAD, SHIJIAZHUANG CITY, HEBEI, CHINA

- Contact: hebei leading