2K Mold

Product Quick Detail

- FOB Price

- USD $200,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Dongguan

- Packaging

- N/A

- Delivery

- 2-5 weeks

Specifications

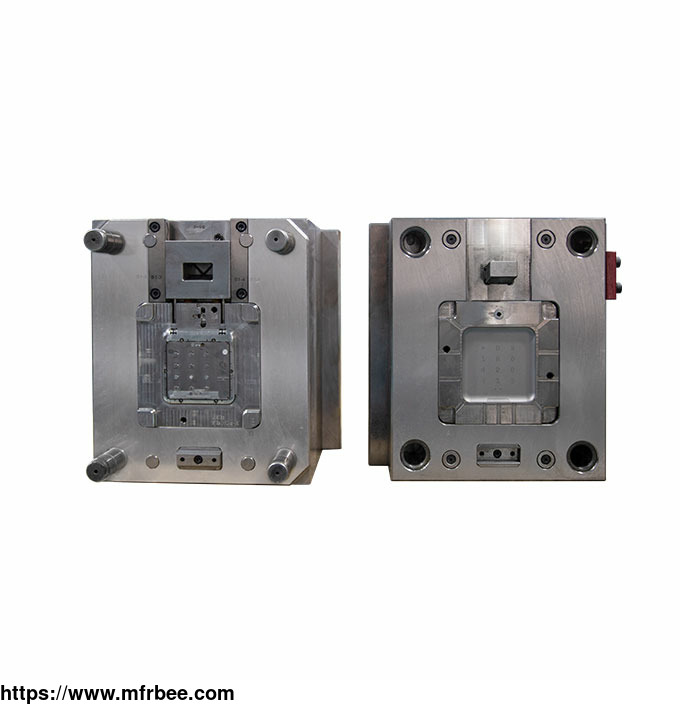

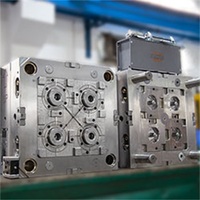

2K Molds

The rotary mold is composed of two-cavity and core sides, the two core sides are the same, only the cavity sides is different which the second color cavity is bigger than the first color, at the

beginning of injection molding, the barrel of the two-color injection molding machine first injects the plastic into the mold cavity of the first color, after it is cured, the core side will be

rotated after solid, then the first color part will be injected to the second color mold by core rotating, then the second injection molding barrel will cover the first color part by injection, the

two-cavity and core sides are continuously produced, then the part will be ejected out by the second color.

2 Shot Mold design key points

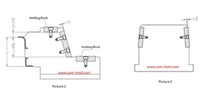

1. The guide pin and pushing of mold base must be symmetrical up and down, and the cavity and core side must be symmetrical.

2. The core sie should be rotated 180 degrees, and the cavity keep the same.

3. The product ranking distance must be based on the distance between the injection molding machine barrel because the distance between the two barrels is fixed.

4. The core side of the 2 parts are the same, the ejector pin is the same too, it is a rotation relationship that can not be made into a translation relationship.

5. The ejector plate can only be reset with a spring or a hydraulic cylinder, and a screw cannot be used for forced reset, because the core site will be rotated.

6. The side locks must be on the four sides of the mold center, the mold cavity and core side are symmetrical, otherwise, the core side will not align with the cavity after rotating 180 degrees.

7. The direction of cooling must be on the side of the top and bottom side, and each circulating water must be on the same surface, the inlet can not enter the top side and the outlet is on the

bottom side because the core side must be rotated 180 degrees, so pay attention to the mold base size cannot higher than the height of the water outlet of the 2k injection molding machine,

otherwise, the water cannot be transported.

8. The first injected part should be placed on the non-operating side, because after the first injection, the product has to be rotated 180 degrees for the second injection, and it just turns to

the operating side for easy access to the part.

9. The parting surface of the core side must be the parting surface obtained after the two parts are merged as the core side; the parting surface of the cavity must be a single part, and the

parting surface of the merged part is not acceptable.

10. After the mold cavity and core side are rotated 180° from the center, they must be matched, which must be checked during design processing.

11. Normally, the hard part will be injected in advance, and then the soft part injected later because the soft part is easy to be deformed.

12. For 2k injection molding, the gate location must be carefully selected, for the first color part, it is better to choose the sub gate which the runner can be cut automatically, then the 3-plate

or hot runner mold can be considered if sub gate mold can not be used.

13. Generally speaking, the shrinkage rate of the two-color mold depends on the first color material, because the first color material has supported the outline of the plastic part, the second

color material will not shrink more. As for how to determine the primary and secondary materials, there are many factors to be considered, such as the fluidity of raw materials, the shape of

plastic products, and so on.

As a plastic injection manufacturer, we will do our best to meet all the needs of customers.

If you want to know more details of insert injection molding, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2017

- Address: No.136 Xingwu Road,Wusha Community, Changan Town,Dongguan, China

- Contact: usm mold