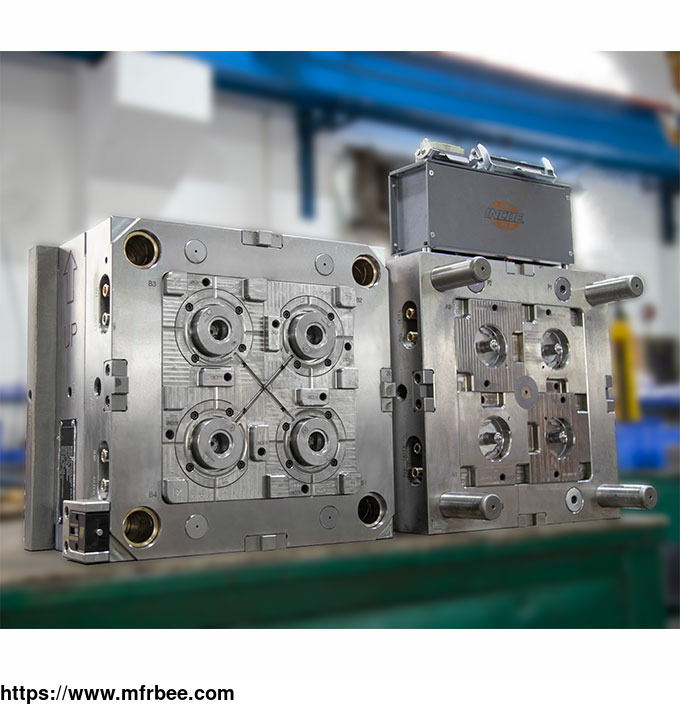

4 Cavity Mold

Product Quick Detail

- FOB Price

- USD $200,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Dongguan

- Packaging

- N/A

- Delivery

- 2-5 weeks

Specifications

4 Cavity Injection Mold

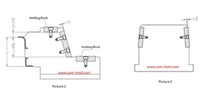

The multi-cavity mold can save production time, for example, one mold can produce 1 piece of part in one minute, but it can be produced 32 pieces of parts in one minute if we make a 32-cavity mold. Multi cavity mold requires very high machining accuracy. If the machining error of one single cavity is 0.01mm, and the total tolerance of 64-cavity processing will be very big. therefore, to make the multi-cavity mold request very advanced processing equipment in order to ensure the machining accuracy.

Advantages of 4 Cavities Plastic Injection Mold

1. Saving production cost: the injection cost can be saved a lot when producing multiple products at the same time. For example, a 64-multi cavity mold can produce 64 pieces of parts in one minute, but if we use one 32-cavity mold which needs to get 64 pieces of parts, then it means it will need to make 2 times, so the production cost will be increased;

2. Saving mold cost: to make 2 sets 32-cavity mold cost is about 1/3 higher than one set 64-cavity mold;

3. Order target achievement rate: it will be difficult for a single cavity mold to produce 1 million parts in a short time, but a multi-cavity mold is easy to deliver on time.

As one of injection molding manufacturers, we will do our best to meet all the needs of customers.

If you want to know more details of predeformation mold, please visit our website.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2017

- Address: No.136 Xingwu Road,Wusha Community, Changan Town,Dongguan, China

- Contact: usm mold